Vinyl Siding Versus Aluminum Siding A Homeowners Guide

Vinyl siding versus aluminum siding: Choosing the right exterior cladding for your home can feel overwhelming. Both options offer durability and aesthetic appeal, but they differ significantly in material composition, lifespan, maintenance needs, and environmental impact. This guide dives into the key differences, helping you make an informed decision that best suits your budget, style preferences, and long-term goals.

We’ll explore everything from initial costs and installation ease to the long-term durability and environmental considerations of each material. Understanding these factors will empower you to choose the siding that not only enhances your home’s curb appeal but also provides lasting value and peace of mind.

Initial Comparison

Choosing between vinyl and aluminum siding involves understanding their manufacturing, lifespan, and cost. Both are popular choices for home exterior cladding, but their properties and price points differ significantly. This comparison will highlight these key differences to aid in your decision-making process.

Manufacturing Processes

Vinyl siding is manufactured through an extrusion process. Polyvinyl chloride (PVC) resin, along with additives for color, impact resistance, and UV protection, are melted and forced through a die to create the desired shape and profile. The resulting siding is then cooled and cut to length. Aluminum siding, on the other hand, is produced using a rolling process. Aluminum coils are passed through a series of rollers that shape and form the siding panels. A protective coating, typically paint, is then applied for weather resistance and aesthetics. The process for aluminum siding involves more steps and often includes specialized finishes for durability.

Lifespan and Warranty Expectations

Vinyl siding typically boasts a lifespan of 20-40 years, depending on quality, installation, and environmental factors. Manufacturers usually offer warranties ranging from 20 to 50 years, often covering defects in materials and workmanship. Aluminum siding, while potentially lasting even longer with proper maintenance, generally has a lifespan of 40-50 years. Warranties on aluminum siding can also extend for several decades, focusing on corrosion resistance and paint adhesion. However, it’s crucial to remember that warranties typically cover defects, not general wear and tear from weathering.

Raw Materials

The primary raw material for vinyl siding is polyvinyl chloride (PVC) resin. Additives like pigments, stabilizers, and impact modifiers are incorporated to enhance its properties. Aluminum siding, as the name suggests, uses aluminum as its main raw material. This aluminum is typically sourced from recycled and virgin aluminum stock. Additional materials include paint or other protective coatings for weather resistance and aesthetic appeal.

Initial Cost Comparison

The initial cost of siding installation varies based on factors such as house size, siding type, labor costs in your region, and the complexity of the installation. However, a general comparison can be made. Note that these are estimates and actual costs can vary significantly.

| Price (USD) | Material (USD) | Labor (USD) | Total Cost (USD) |

|---|---|---|---|

| Vinyl | $2,000 – $4,000 | $2,000 – $4,000 | $4,000 – $8,000 |

| Aluminum | $3,000 – $6,000 | $2,500 – $5,000 | $5,500 – $11,000 |

Aesthetic Considerations

Source: homeprofy.com

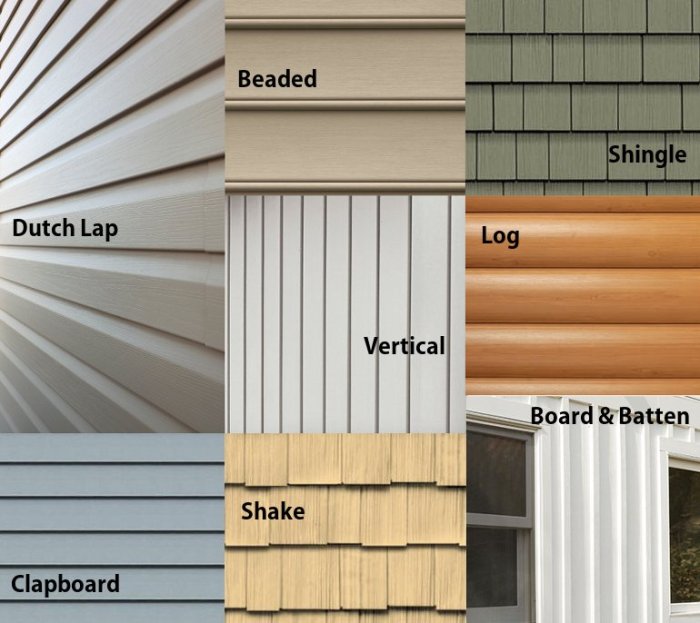

Choosing between vinyl and aluminum siding often comes down to personal preference, and a big part of that is the look. Both materials offer a variety of styles and colors, but their capabilities and maintenance needs differ significantly. Let’s explore the aesthetic options and upkeep involved.

Color and Texture Variety, Vinyl siding versus aluminum siding

Vinyl siding boasts a wider array of colors and textures than aluminum. While aluminum siding traditionally offered a limited palette of muted tones, advancements have expanded the options. However, vinyl consistently provides more choices, including wood grain effects, stone finishes, and even colors designed to mimic popular paint schemes. The textures in vinyl are often more pronounced and realistic, offering a more tactile and visually interesting surface. Aluminum, while improving, tends to maintain a smoother, more uniform finish.

Mimicking Other Materials

Both vinyl and aluminum siding attempt to replicate the look of other materials, primarily wood and stone. Vinyl siding excels in this area, with manufacturers offering incredibly realistic wood grain patterns and textures that are often difficult to distinguish from real wood at a distance. Aluminum siding’s ability to mimic natural materials is more limited; its smoother surface makes it harder to convincingly replicate the intricate details of wood or stone. While some textured aluminum siding exists, it often lacks the depth and variation of vinyl’s options.

Maintenance Requirements

Maintaining the appearance of your siding is crucial. Vinyl siding is generally low-maintenance. Regular cleaning with soap and water is usually sufficient to remove dirt and debris. Its non-porous surface resists staining and mildew. Aluminum siding also requires minimal maintenance; however, its smooth surface can show scratches and dents more readily than vinyl. Aluminum is also susceptible to oxidation, resulting in a dulling or discoloration over time. Regular washing and occasional touch-up paint might be needed to maintain its appearance.

Design Examples

Example 1: Vinyl Siding – Imagine a two-story home clad in a deep charcoal gray vinyl siding with a subtle wood grain texture. Large, 12-inch wide panels create a clean, modern look. The trim is a contrasting creamy white, accentuating the windows and doors. This combination offers a sophisticated, yet low-maintenance exterior.

Example 2: Aluminum Siding – Picture a ranch-style home featuring a smooth, light gray aluminum siding. The panels are slightly smaller, approximately 8 inches wide, giving a more traditional appearance. The trim is a darker gray, creating a subtle yet effective contrast. This design is clean, simple, and reflects light well, keeping the home cooler in sunny climates.

Example 3: Vinyl Siding – Consider a cottage-style home with vinyl siding that mimics the look of weathered cedar shingles. Smaller, 6-inch panels are used to create a more textured and rustic appearance. The color is a warm, medium brown with variations in tone to enhance the illusion of natural wood. White trim provides a classic, charming contrast.

Example 4: Aluminum Siding – Visualize a contemporary home with a sleek, dark bronze aluminum siding. Large, 16-inch panels create a minimalist aesthetic. The trim is a matching dark bronze, further emphasizing the clean lines of the design. This choice provides a modern and sophisticated feel with low-maintenance upkeep.

Durability and Maintenance

Source: costowl.com

Choosing between vinyl and aluminum siding involves considering their long-term performance and the maintenance they require. Both materials offer decent durability, but their strengths and weaknesses differ significantly regarding impact resistance, weathering, and overall upkeep. Understanding these differences is crucial for making an informed decision that aligns with your budget and lifestyle.

Both vinyl and aluminum siding are designed to withstand the elements, but their responses to damage and aging vary. Vinyl, while generally impact-resistant, can crack or dent under significant force, particularly in colder climates where it becomes more brittle. Aluminum, being a metal, is more resistant to dents and impacts but can be susceptible to denting from heavier objects. Both materials can be scratched, though scratches on aluminum are often more noticeable due to the material’s reflective nature. Over time, both can fade or discolor, though the rate and extent vary depending on factors like sun exposure and the quality of the siding.

Impact Resistance and Scratch Resistance

Vinyl siding generally withstands minor impacts well, bouncing back from small knocks and bumps. However, heavier impacts, such as a falling branch or a forceful hit from a tool, can cause cracks or dents, especially in colder temperatures. Aluminum siding, being a metal, offers superior resistance to dents and impacts, but it can still be scratched or dented by forceful impacts. Scratches on aluminum are usually more visible than on vinyl due to the reflective nature of the material. Repairing dents in vinyl often involves replacing the damaged section, while dents in aluminum might be repairable through careful hammering or specialized repair kits.

Weathering and Fading

Both vinyl and aluminum siding are susceptible to fading and discoloration over time, primarily due to prolonged sun exposure. UV rays can degrade the pigments in vinyl siding, causing it to lose its vibrancy and become chalky. Aluminum siding can also fade, although it’s generally more resistant to UV degradation than vinyl. Additionally, both materials can be affected by environmental factors such as rain, snow, and extreme temperature fluctuations. Regular cleaning and maintenance can help mitigate the effects of weathering and prolong the life of both types of siding. For instance, a house in a sunny, coastal climate might show more significant fading in both types of siding than a house in a shaded, inland area.

Cleaning and Maintenance Procedures

Proper cleaning and maintenance are essential for preserving the appearance and extending the lifespan of both vinyl and aluminum siding.

Here’s a step-by-step guide for maintaining both:

- Preparation: Inspect the siding for any loose or damaged pieces. Clear away any debris such as leaves, twigs, or cobwebs.

- Cleaning Solution: For both vinyl and aluminum, a mixture of mild detergent and water is generally sufficient. Avoid harsh chemicals or abrasive cleaners.

- Washing: Use a soft-bristled brush or sponge to gently scrub the siding. Rinse thoroughly with clean water. For larger areas, a pressure washer can be used, but maintain a safe distance to avoid damaging the siding.

- Drying: Allow the siding to air dry completely. Avoid using high-pressure water streams to prevent water damage.

- Inspection: After cleaning, carefully inspect the siding for any damage that needs repair.

Long-Term Issues and Repair Methods

Over time, both vinyl and aluminum siding can experience issues that may require repair.

Examples for Vinyl Siding:

- Cracks and Dents: These are usually repaired by replacing the damaged section of siding. This often requires some DIY skills or professional assistance.

- Fading and Chalking: While some fading is inevitable, severe discoloration can be addressed by using vinyl siding cleaners designed to restore color.

Examples for Aluminum Siding:

- Dents: Minor dents can sometimes be repaired by carefully hammering them out from the back. Severe dents may require panel replacement.

- Corrosion: Aluminum is resistant to corrosion, but prolonged exposure to harsh elements can cause it. Damaged areas may require replacement or repainting.

Environmental Impact and Sustainability: Vinyl Siding Versus Aluminum Siding

Source: sidingauthority.com

Choosing between vinyl and aluminum siding involves considering more than just aesthetics and durability; the environmental impact of each material is a significant factor. Both have pros and cons regarding manufacturing, lifespan, and disposal, impacting our planet’s resources and health. Let’s delve into the specifics.

Manufacturing Impacts

The manufacturing processes for vinyl and aluminum siding differ significantly, leading to varying environmental footprints. Vinyl siding production relies heavily on fossil fuels, resulting in substantial greenhouse gas emissions during the creation of polyvinyl chloride (PVC). The process also involves the use of various chemical additives, some of which may pose environmental risks. Aluminum siding, while requiring energy for mining bauxite and refining it into aluminum, generally has a lower carbon footprint per unit than vinyl, particularly if renewable energy sources are used in the process. However, the mining process itself can have significant environmental impacts, including habitat destruction and water pollution.

Lifespan Impacts

The longevity of each siding type contributes to its overall environmental impact. Vinyl siding, known for its durability, can last for several decades, reducing the frequency of replacements. However, its non-biodegradable nature means it persists in landfills for a very long time. Aluminum siding also boasts a considerable lifespan, potentially lasting even longer than vinyl in some applications. However, its eventual disposal presents similar challenges to vinyl. The long-term effects of both materials’ potential leaching into the environment (though generally considered minimal with proper installation) remain a consideration.

Recycling and Disposal

Recycling options for vinyl siding are limited, with many communities lacking effective recycling programs for this material. Disposal usually involves sending it to landfills, contributing to waste accumulation. Aluminum siding, on the other hand, is readily recyclable and has a high recycling rate. Recycling aluminum requires significantly less energy than producing new aluminum from raw materials, making it a more environmentally friendly option from a lifecycle perspective.

Comparative Table

| Material | Manufacturing Impact | Lifespan Impact | Recycling/Disposal |

|---|---|---|---|

| Vinyl Siding | High energy consumption, greenhouse gas emissions, use of chemical additives. | Long lifespan, but non-biodegradable, leading to landfill accumulation. | Limited recycling options, primarily landfill disposal. |

| Aluminum Siding | Energy intensive mining and refining, but potentially lower carbon footprint than vinyl if renewable energy is used. | Long lifespan, reducing replacement frequency. | Readily recyclable, high recycling rate, reducing landfill burden. |

Installation and Repair

Source: advancedwindowsystems.com

Choosing between vinyl and aluminum siding often comes down to more than just aesthetics; installation and repair costs play a significant role in the overall budget. Both materials have their own set of advantages and disadvantages when it comes to ease of installation, repair complexity, and associated expenses. Understanding these differences is crucial for making an informed decision.

Installation ease and cost vary considerably between vinyl and aluminum siding. Vinyl is generally considered easier for DIY enthusiasts, while aluminum often requires more specialized tools and expertise, leading to higher labor costs. Repairing damaged sections also differs in complexity and expense. Let’s delve into the specifics.

Installation Ease and Required Expertise

Vinyl siding is known for its relative ease of installation. The interlocking design allows for quick and straightforward panel placement. Basic hand tools, such as a measuring tape, level, utility knife, and hammer, are usually sufficient. While professional installation is always an option, many homeowners successfully tackle vinyl siding projects themselves. Aluminum siding, however, often necessitates more specialized tools and techniques. Its installation usually involves rivets, screws, and potentially specialized fastening tools, often requiring the expertise of a professional siding installer. This increased complexity translates to higher labor costs.

Installation Costs

The cost of installing siding varies depending on several factors including the size of the project, the complexity of the house’s design, and regional labor rates. However, a general estimate suggests that vinyl siding installation typically costs between $3 and $8 per square foot, including materials and labor. This range accounts for variations in material quality and labor costs across different regions. Aluminum siding installation, due to its more complex process, usually falls within a higher price range, typically between $6 and $12 per square foot, again factoring in material quality and labor costs. These are just estimates, and it’s always advisable to obtain multiple quotes from reputable contractors.

Repairing Damaged Sections

Repairing damaged vinyl siding is relatively straightforward. Individual panels can often be replaced without affecting surrounding sections. The cost is typically lower, primarily involving the cost of the replacement panel and labor for its installation. Replacing damaged aluminum siding, on the other hand, can be more challenging. Aluminum siding is more prone to dents and scratches, and repairing these imperfections might require specialized tools or even panel replacement. The cost of repair is usually higher due to the specialized labor needed and potentially higher material costs.

Step-by-Step Installation of a Single Panel

The installation process differs significantly between vinyl and aluminum siding.

Vinyl Siding Installation

- Measure and cut the vinyl siding panel to the required length, ensuring a snug fit.

- Using a level, position the panel against the existing siding, ensuring proper alignment and overlap.

- Snap the panel into place, ensuring it securely interlocks with the adjacent panels.

- Repeat for subsequent panels, ensuring consistent overlap and alignment.

Aluminum Siding Installation

- Measure and cut the aluminum siding panel to the required length using appropriate metal-cutting tools.

- Position the panel against the existing siding, using a level to ensure proper alignment.

- Secure the panel using rivets or screws, ensuring that the fasteners are properly spaced and aligned.

- Caulk any gaps or seams to prevent water infiltration.

Final Wrap-Up

Ultimately, the “best” siding – vinyl or aluminum – depends entirely on your individual needs and priorities. Weighing the pros and cons of each, considering factors like budget, desired aesthetic, maintenance preferences, and environmental concerns, will lead you to the perfect choice for your home. Remember to get multiple quotes from reputable contractors to ensure a smooth and successful installation process. Happy siding!

FAQ Compilation

Can I paint vinyl siding?

Generally, no. Vinyl siding is designed with its color baked in. Painting it can void warranties and damage the siding.

How do I repair a dent in aluminum siding?

Minor dents in aluminum siding can often be gently pushed back into place from the back. Larger dents may require replacement of the damaged panel.

Which siding is better for coastal areas?

Aluminum siding tends to hold up better in harsh coastal environments due to its superior resistance to salt spray and corrosion.

Is vinyl siding recyclable?

Some vinyl siding can be recycled, but the process isn’t widely available. Check with your local waste management facility for options.

What’s the average lifespan of each siding type?

Vinyl siding typically lasts 20-40 years, while aluminum siding can last 50 years or more with proper maintenance.

Comments are closed.