Steel Siding vs Vinyl Cost A Homeowners Guide

Steel siding vs vinyl cost: Choosing the right siding for your home involves more than just aesthetics. This guide dives into a comprehensive cost comparison, examining initial investment, long-term expenses, durability, installation, and the overall impact on your home’s value and curb appeal. We’ll break down the factors influencing price, from material quality and regional labor costs to unexpected repairs and maintenance needs. Get ready to make an informed decision!

Understanding the financial implications of each option is crucial. We’ll explore how factors like material thickness, color choices, and even the complexity of your home’s design affect the final cost. We’ll also compare the long-term costs associated with maintenance, repairs, and potential replacements over the lifespan of each siding type. By the end, you’ll have a clearer picture of which siding best suits your budget and long-term goals.

Initial Cost Comparison

Choosing between steel and vinyl siding involves careful consideration of various factors, not least of which is the initial cost. While both options offer durable exterior cladding, their price points differ significantly, influenced by material quality, installation complexity, and regional variations. This section breaks down the cost differences to help you make an informed decision.

Generally, steel siding tends to be more expensive upfront than vinyl siding. However, the price difference isn’t always dramatic and depends heavily on the specifics of your project. Several factors contribute to the final cost, including material thickness, color selection, and the complexity of your home’s exterior. Regional differences in labor costs also play a significant role.

Average Price Per Square Foot

The average cost per square foot for steel siding installation ranges from $8 to $15, while vinyl siding typically costs between $3 and $12 per square foot. These are broad ranges, and the actual cost can vary considerably depending on the factors discussed below.

Factors Influencing Initial Cost

Several factors contribute to the final cost of both steel and vinyl siding installations. The table below summarizes these factors and their impact on pricing.

| Factor | Steel Siding Impact | Vinyl Siding Impact | Example |

|---|---|---|---|

| Material Thickness | Higher thickness = higher cost; thicker steel offers greater durability. | Thickness affects durability and price; thicker vinyl is more resistant to damage. | 26-gauge steel is generally more expensive than 29-gauge. Thicker vinyl (e.g., .046 inch) costs more than thinner options (.040 inch). |

| Color Choices | Custom colors and finishes (e.g., textured) can increase costs. | A wider range of colors is usually available, with some premium colors costing more. | A metallic finish on steel siding is typically more expensive than a solid color. Similarly, certain wood-grain vinyl options may cost more than solid colors. |

| Installation Complexity | Complex designs, multiple angles, and difficult-to-access areas increase labor costs. | Similar to steel, complex designs and difficult access increase labor costs. | A home with many dormers or intricate architectural details will cost more to insulate than a simple rectangular structure. |

| Regional Labor Rates | Higher labor costs in certain regions directly impact the overall installation price. | Labor costs vary regionally, influencing the total installation cost. | Labor rates in major metropolitan areas are generally higher than in rural areas, affecting both steel and vinyl siding installations. |

Upfront Costs Beyond Material and Labor

Beyond the cost of materials and labor, several other upfront expenses should be factored into your budget. These can significantly impact the total project cost.

- Permits: Building permits are often required for exterior renovations and vary in cost depending on your location and project scope.

- Delivery Fees: Transportation costs for siding materials can be substantial, especially for larger projects or remote locations.

- Waste Disposal: Removing old siding and disposing of it properly adds to the overall cost. This is especially relevant if you’re replacing existing siding.

- Preparation and Repair: Any necessary repairs to the underlying structure before siding installation will add to the overall expense.

Long-Term Cost Analysis

Choosing between steel and vinyl siding involves considering not just the upfront cost, but also the long-term expenses associated with maintenance, repairs, and eventual replacement. While vinyl might seem cheaper initially, a comprehensive long-term analysis reveals a more nuanced picture. Factors like climate, maintenance practices, and unexpected issues significantly impact the overall cost of ownership.

Lifespan and Weather Impact, Steel siding vs vinyl cost

Steel siding generally boasts a longer lifespan than vinyl siding, typically lasting 30-50 years or more with proper maintenance. Vinyl siding, on the other hand, usually lasts 20-30 years, though this can be significantly reduced in harsh climates with extreme temperature fluctuations, intense sun exposure, or frequent hailstorms. For example, a home in Arizona with significant sun exposure might see vinyl siding fade and become brittle much faster than one in a milder climate like Oregon. The material’s durability is directly tied to the quality of the vinyl; higher-quality vinyl tends to be more UV-resistant and less prone to damage. Steel siding’s superior durability is largely due to its resistance to impact, fading, and rot, making it a more robust choice in challenging weather conditions.

Maintenance Costs and Common Issues

Both steel and vinyl siding require some level of maintenance, but the nature and frequency differ considerably. Vinyl siding primarily needs periodic cleaning to remove dirt, grime, and mildew. Power washing is generally recommended, but it’s crucial to use the correct nozzle and pressure to avoid damaging the siding. Common vinyl siding issues include cracking, fading, and warping, which may necessitate costly repairs or even section replacements. Repairing a single damaged vinyl panel might cost between $50 and $200 depending on the extent of the damage and labor costs.

Steel siding requires less frequent cleaning. While it can be power washed, it’s generally more resistant to dirt and mildew buildup. However, steel siding can be susceptible to scratches and dents, especially from hail or impacts from flying debris. Repairing dents might involve repainting or replacing individual panels, with costs ranging from $100 to $300 per panel depending on the size and complexity of the repair. Rust is another potential issue, though modern steel siding is often coated with zinc or other protective layers to mitigate this risk.

Hidden Costs and Premature Degradation

Hidden costs can significantly impact the total cost of ownership. For vinyl siding, unexpected issues like insect infestation (particularly carpenter ants) can lead to extensive damage, necessitating costly repairs or replacements. Furthermore, improper installation of vinyl siding can lead to premature failure, resulting in moisture intrusion and subsequent rot.

Steel siding, while durable, can suffer from issues like corrosion if the protective coating is damaged. This is more likely in coastal areas or areas with high humidity. Furthermore, while less frequent, significant hail damage can necessitate costly repairs or panel replacements.

Total Cost of Ownership (20-Year Projection)

The following table provides a simplified estimate of the total cost of ownership over 20 years. Note that these figures are estimates and can vary significantly depending on factors such as location, climate, maintenance practices, and the quality of materials used.

| Cost Category | Steel Siding | Vinyl Siding |

|---|---|---|

| Initial Cost | $10,000 – $15,000 | $7,000 – $12,000 |

| Maintenance (Cleaning, Minor Repairs) | $500 – $1,000 | $1,000 – $2,000 |

| Major Repairs/Replacements | $1,000 – $3,000 | $2,000 – $5,000 |

| Total Estimated Cost (20 Years) | $11,500 – $19,000 | $10,000 – $19,000 |

Material Properties and Durability: Steel Siding Vs Vinyl Cost

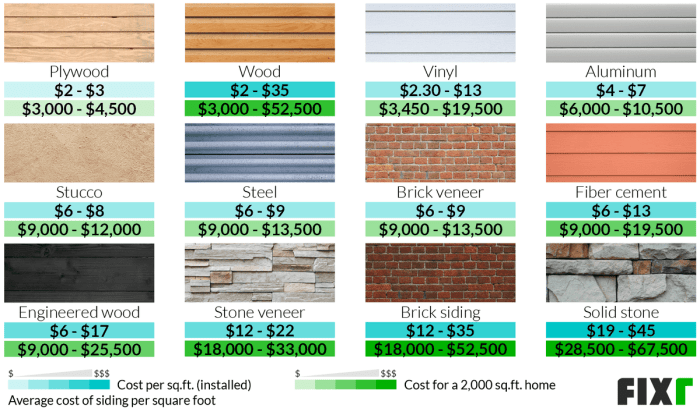

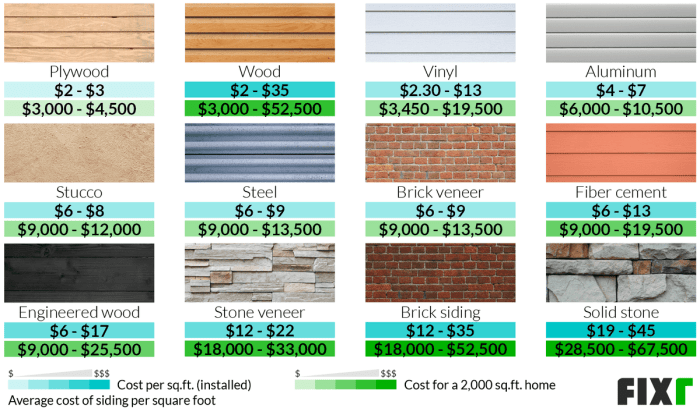

Source: fixr.com

Choosing between steel and vinyl siding involves understanding their inherent differences in durability and how they withstand the elements. Both materials offer advantages, but their strengths lie in different areas, making one a better choice depending on your specific needs and climate. Let’s delve into the specifics of their material properties.

Impact Resistance and Damage

Steel siding boasts significantly higher impact resistance compared to vinyl. A thrown rock or a wayward baseball will likely leave a dent in vinyl, while steel is much more likely to withstand such impacts without visible damage. However, severe impacts can damage both materials. Imagine a scenario where a large tree branch falls on your house: While the steel siding might show only a localized dent, the vinyl siding could crack or even puncture. Conversely, vinyl is more resistant to scratches; minor scrapes will be far less noticeable on vinyl than on steel. The glossy finish of steel makes scratches more visible. Therefore, the “best” material depends on the anticipated type of damage your home is most likely to encounter. A home in a wooded area might benefit more from the impact resistance of steel, while a home in a suburban setting where accidental scrapes are more common might be better suited for vinyl.

Weather Resistance

Steel siding excels in extreme weather conditions. Its robust construction withstands strong winds, heavy snowfall, and extreme temperatures better than vinyl. Imagine a blizzard: Steel siding is less likely to be damaged by the weight of accumulated snow compared to vinyl, which can become brittle and crack in freezing temperatures. Conversely, vinyl is less prone to rust and corrosion, a significant concern for steel siding, particularly in coastal areas or regions with high humidity. While modern steel siding often has protective coatings to prevent rust, these coatings can eventually degrade, leaving the steel vulnerable. Vinyl, being a plastic polymer, inherently resists rust and rot.

UV Exposure and Color Retention

Both steel and vinyl siding are susceptible to UV degradation, but the effects manifest differently. Imagine two houses, one with steel and one with vinyl siding, exposed to years of intense sunlight. The steel siding might show some fading, but its structural integrity generally remains intact. The color might become slightly muted or uneven, but the underlying metal remains strong. A visual representation would show a slightly faded, but otherwise solid, steel panel compared to a possibly warped or cracked vinyl panel. Conversely, prolonged UV exposure can cause vinyl siding to fade significantly, become brittle, and even warp. The vinyl’s color may become chalky and lose its vibrancy, potentially cracking under stress. The image comparison would highlight a pronounced color change and potentially visible cracking in the vinyl, while the steel panel, while faded, would maintain its shape and structural integrity. Therefore, the long-term color retention of steel tends to be superior to that of vinyl, although both will eventually degrade with prolonged UV exposure.

Installation Considerations

Source: squeegeesquad.com

Choosing between steel and vinyl siding involves more than just upfront costs; the installation process significantly impacts the overall project timeline and expense. Steel and vinyl siding installations differ considerably in complexity, required skill sets, and environmental impact. Understanding these differences is crucial for making an informed decision.

Steel siding installation is generally considered more complex and time-consuming than vinyl siding installation. This is due to the heavier weight of steel panels and the need for more precise cutting and fastening. While vinyl siding can often be installed by a reasonably handy homeowner, steel siding installation is usually best left to experienced professionals.

Installation Process Complexity and Time

Steel siding requires more precision in cutting and fitting due to its rigidity. Improper installation can lead to gaps and leaks, compromising the siding’s weather resistance. The heavier weight of steel panels also demands more robust fastening techniques and potentially specialized tools. A typical steel siding installation might take longer, possibly several days for a larger house, whereas vinyl siding installation, depending on the size of the house and installer’s experience, might be completed within a day or two. This difference translates to higher labor costs for steel siding. Vinyl siding’s flexibility and lighter weight allow for quicker installation, potentially reducing labor costs.

Specialized Tools and Skills

Installing steel siding necessitates specialized tools such as powerful shears for cutting, specialized fasteners designed for steel, and potentially a pneumatic nailer for faster and more consistent installation. A high level of precision and experience is required to ensure proper overlap and watertight seals. Vinyl siding installation, while still benefiting from the use of specialized tools like a vinyl siding cutter, is less demanding in terms of skill and precision. Basic carpentry skills and familiarity with common hand tools are generally sufficient.

Environmental Impact

Both steel and vinyl siding have environmental implications throughout their lifecycle, from manufacturing to disposal. Steel siding manufacturing is energy-intensive, requiring significant energy for steel production and transportation. However, steel is highly recyclable, mitigating its environmental impact at the end of its life. Vinyl siding, while often cheaper initially, is primarily manufactured from petroleum-based materials, contributing to carbon emissions. Vinyl’s recyclability is limited, and improper disposal can lead to environmental pollution. Waste generation during installation is also a factor; steel siding typically generates less waste due to its precision-cut nature, but the heavier material may require more careful handling. Vinyl siding’s flexibility might lead to more scrap material, particularly for complex architectural details. Furthermore, both types of siding may contain harmful chemicals during manufacturing, which are then released over the lifetime of the product.

Aesthetic Considerations and Design Options

Source: tonyslifetimeexteriors.com

Choosing between steel and vinyl siding often comes down to personal preference and the overall aesthetic you’re aiming for. Both materials offer a wide range of colors and styles, but their inherent properties lead to different visual impacts on a home. Understanding these differences is key to making the right choice for your project.

Steel and vinyl siding present distinct aesthetic qualities. Steel siding, with its clean lines and modern feel, often projects a more contemporary or industrial look. Vinyl, on the other hand, can mimic the appearance of various materials like wood, stone, or even stucco, offering a wider range of traditional or rustic styles. The color palettes also differ; steel siding tends to offer a more limited range of colors that are typically more consistent and less prone to fading, while vinyl boasts a much broader spectrum, sometimes including more vibrant and unusual shades.

Steel Siding Aesthetics

Steel siding’s smooth, flat surface creates a sleek, modern look. Its subtle sheen can add a touch of sophistication, particularly in contemporary architectural designs. While color options might be less varied than vinyl, the colors tend to be deeper and more saturated, lending a more robust visual impact. For example, a deep charcoal gray steel siding on a minimalist home creates a striking contrast against a lighter-colored exterior. The clean lines of steel siding complement architectural styles like mid-century modern, contemporary, and industrial designs. Steel’s durability also means the color remains consistent over time, avoiding the chalkiness that can sometimes affect vinyl.

Vinyl Siding Aesthetics

Vinyl siding excels in its versatility. It can convincingly mimic the look of wood shake, clapboard, or even stone, making it suitable for a wide range of architectural styles. This flexibility allows homeowners to achieve a specific aesthetic without the high cost of natural materials. Imagine a Victorian home clad in vinyl siding designed to resemble wood shingles; the effect can be quite charming and historically accurate. Furthermore, vinyl siding offers a far broader spectrum of colors and patterns, allowing for more personalized and creative design choices. However, it’s important to note that the vibrancy of some vinyl colors can fade over time, especially with prolonged sun exposure.

Advantages and Disadvantages of Each Material’s Curb Appeal

The following points highlight the pros and cons of each siding material concerning visual impact and curb appeal:

Let’s compare the aesthetic benefits and drawbacks of steel and vinyl siding to help you decide which best suits your home’s style and your personal preferences.

- Steel Siding Advantages: Clean, modern look; durable color consistency; sophisticated sheen; low maintenance.

- Steel Siding Disadvantages: Fewer color choices; can appear stark or industrial in some settings; dents are more visible than on vinyl.

- Vinyl Siding Advantages: Wide range of colors and textures; can mimic other materials; relatively inexpensive; easy installation.

- Vinyl Siding Disadvantages: Can fade over time; prone to cracking and warping in extreme temperatures; less durable than steel; may appear less sophisticated.

Epilogue

Ultimately, the “best” siding – steel or vinyl – depends entirely on your individual needs and priorities. While vinyl offers a lower upfront cost, steel often boasts superior durability and longevity, potentially saving you money in the long run. Carefully weigh the initial investment against the long-term costs, considering your home’s climate, your personal aesthetic preferences, and your budget. This detailed comparison empowers you to make a confident and cost-effective choice for your home improvement project.

Q&A

What are the typical warranties offered for steel and vinyl siding?

Warranties vary by manufacturer and product line, but generally, steel siding warranties range from 20-50 years, while vinyl siding warranties typically last 20-30 years. Always check the specific warranty details before purchasing.

Can I install steel or vinyl siding myself?

While some DIY-savvy homeowners attempt vinyl siding installation, steel siding installation is generally best left to professionals due to its weight and specialized tools required. Improper installation can void warranties and lead to costly repairs.

How does insurance affect the cost of siding repairs?

Comprehensive homeowner’s insurance often covers damage to siding from events like hail or windstorms. However, normal wear and tear isn’t typically covered. Check your policy details to understand your coverage.

What’s the impact of climate on siding lifespan?

Extreme weather conditions can significantly affect siding lifespan. Harsh sun, freezing temperatures, and heavy snowfall can cause faster degradation in both steel and vinyl, though steel generally withstands these better.

Are there financing options available for siding replacements?

Many home improvement retailers and contractors offer financing plans, and some lenders specialize in home improvement loans. Explore your options to find the best financing solution for your budget.

Comments are closed.