Ribbed Metal Siding A Complete Guide

Ribbed metal siding offers a durable and stylish exterior cladding option for homes and businesses. From its diverse material choices – including aluminum, steel, and zinc – to its varied profiles and color options, ribbed metal siding provides a wealth of design possibilities. This guide will explore everything from installation techniques and maintenance tips to cost considerations and environmental impact, empowering you to make an informed decision about this increasingly popular exterior material.

We’ll delve into the specifics of different metal types, comparing their longevity and aesthetic appeal. We’ll also cover the installation process step-by-step, providing practical advice on securing watertight seals and avoiding common pitfalls. Finally, we’ll address long-term maintenance, cost-effectiveness, and the environmental considerations surrounding ribbed metal siding, helping you weigh its pros and cons.

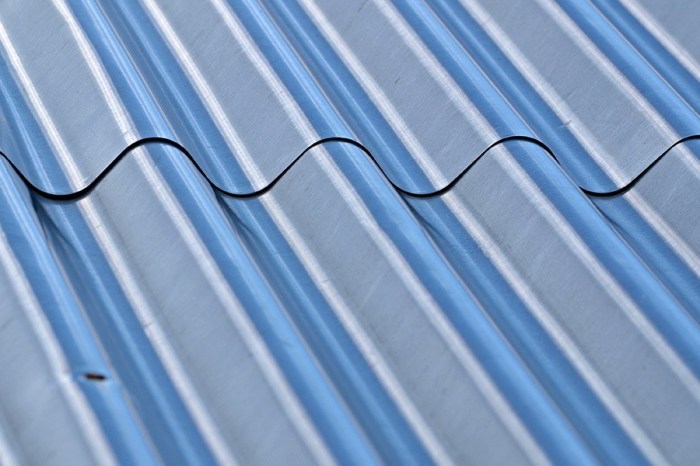

Types of Ribbed Metal Siding

Source: b-cdn.net

Ribbed metal siding offers a durable and aesthetically pleasing exterior cladding option for homes and businesses. Its strength, longevity, and variety of styles make it a popular choice for many building projects. Understanding the different types available is crucial for making an informed decision.

Materials Used in Ribbed Metal Siding Manufacturing

Several materials are used to manufacture ribbed metal siding, each offering a unique set of properties. The most common include aluminum, steel, and zinc. The choice of material significantly impacts the siding’s lifespan, maintenance requirements, and overall cost.

Durability Comparison of Aluminum, Steel, and Zinc Ribbed Metal Siding

Aluminum siding is lightweight and resistant to corrosion, making it a low-maintenance option. However, it’s less dent-resistant than steel. Steel siding, while heavier and potentially more prone to rusting without proper coatings, offers superior strength and impact resistance. Zinc siding, known for its exceptional corrosion resistance and self-healing properties, provides a long-lasting and sustainable solution, although it can be more expensive than aluminum or steel. Properly coated steel siding, however, often matches or exceeds zinc’s lifespan in many climates.

Aesthetic Qualities of Different Ribbed Metal Siding Profiles

The visual appeal of ribbed metal siding varies significantly depending on the profile chosen. Corrugated profiles, with their pronounced waves, create a more rustic or industrial look. Ribbed profiles, featuring less pronounced ridges, offer a cleaner, more contemporary aesthetic. Other profiles, such as vertical rib or batten profiles, provide distinct visual textures and styles to suit different architectural designs. The choice of profile greatly impacts the overall appearance of the building. For example, a corrugated profile might suit a barn or industrial building, while a ribbed profile might be more appropriate for a modern home.

Color Options and Fade Resistance of Ribbed Metal Siding

Ribbed metal siding is available in a vast array of colors, allowing for significant customization to match any architectural style or personal preference. Popular choices often include earth tones, neutral grays, and classic whites. However, vibrant colors are also available. The fade resistance of the color depends heavily on the quality of the coating applied during manufacturing. High-quality coatings, such as Kynar 500® or PVDF, offer superior UV protection and significantly extend the life of the color, preventing premature fading and chalking. For example, a house with Kynar 500® coated siding might retain its color vibrancy for 20-30 years, while a house with a less durable coating may require repainting sooner.

Installation Methods

Installing ribbed metal siding is a straightforward process, but proper preparation and technique are crucial for a long-lasting, watertight finish. This section details the steps involved, from wall preparation to final fastening, ensuring a professional-looking result.

Wall Preparation for Ribbed Metal Siding

Before installing any siding, thorough wall preparation is essential. This involves cleaning the surface to remove any loose debris, dirt, or old paint. For wooden walls, check for rot or damage and repair as needed. Concrete walls should be inspected for cracks and imperfections, which can be filled with appropriate patching compound. Ensure the wall is structurally sound and level; significant unevenness may require shimming or other corrective measures. Finally, apply a suitable primer or sealant to improve adhesion and protect against moisture.

Attaching Ribbed Metal Siding to Different Wall Materials

The method of attaching ribbed metal siding varies slightly depending on the underlying wall material. For wood-framed walls, use corrosion-resistant screws directly into the studs. Ensure proper spacing between fasteners according to manufacturer’s instructions. For concrete or masonry walls, you’ll need to use appropriate fasteners designed for these materials, such as concrete screws or expansion anchors. These fasteners must be installed according to their specific instructions to ensure a secure hold. Metal furring strips can also be used to create a consistent surface for attachment, particularly useful on uneven walls.

Fastening Methods for Ribbed Metal Siding

Several fastening methods exist for ribbed metal siding, each with its advantages and disadvantages. Self-tapping screws are commonly used for their ease of installation and secure hold. However, over-tightening can damage the siding. Hidden fastener systems offer a cleaner, more aesthetically pleasing finish, but they can be more complex to install and may be more expensive. Rivets provide a very strong and durable fastening solution, but require specialized tools and can be noisy. The choice of fastening method will depend on the specific project requirements, budget, and desired aesthetic outcome.

Ensuring Watertight Seals and Preventing Leaks

Watertight seals are paramount to prevent leaks and damage to the underlying structure. Proper overlapping of siding panels is crucial, ensuring a minimum overlap as specified by the manufacturer. Caulk should be applied to all seams and joints, particularly around windows and doors, to create a watertight barrier. Use a high-quality, weather-resistant caulk specifically designed for exterior applications. Regularly inspect the siding for any signs of damage or leaks and address any issues promptly.

Step-by-Step Installation Guide

The following table provides a step-by-step guide to installing ribbed metal siding. Remember to always consult the manufacturer’s instructions for specific details and recommendations.

| Step | Materials | Tools | Description |

|---|---|---|---|

| 1. Prepare the Wall | Cleaning supplies, patching compound (if needed), primer/sealant | Putty knife, brushes, scraper | Clean the wall thoroughly, repair any damage, and apply primer/sealant. Ensure the wall is level and structurally sound. A clean, level surface ensures proper siding installation and prevents future problems. |

| 2. Install Furring Strips (if necessary) | Furring strips, screws or nails | Drill, level, measuring tape | Attach furring strips to the wall to create a level surface for siding installation, especially important on uneven walls. Ensure proper spacing and alignment. |

| 3. Install Starting Strip | Starting strip, screws or nails | Drill, level, measuring tape | Install the starting strip at the bottom of the wall, ensuring it is level and plumb. This provides a solid base for the rest of the siding. |

| 4. Install Siding Panels | Ribbed metal siding panels, fasteners (screws, rivets, etc.), caulk | Drill, screwdriver, rivet gun (if applicable), caulk gun | Install siding panels, overlapping them according to manufacturer’s instructions. Use appropriate fasteners and ensure they are properly spaced. Apply caulk to all seams and joints. A consistent overlap prevents water intrusion. |

| 5. Install J-Channel and Trim | J-channel, trim pieces, fasteners, caulk | Drill, screwdriver, caulk gun, measuring tape | Install J-channel around windows, doors, and corners. Install trim pieces to finish the edges of the siding. Apply caulk to ensure watertight seals. Proper trim installation creates a professional and finished look. |

| 6. Final Inspection | None | Visual inspection | Inspect the entire installation for any gaps, loose fasteners, or other imperfections. Address any issues promptly. A final inspection ensures a high-quality installation free of defects. |

Maintenance and Repair

Source: gnmcusa.com

Ribbed metal siding, while durable, requires regular maintenance to keep it looking its best and extending its lifespan. Neglecting these tasks can lead to costly repairs down the line. This section details the essential maintenance and repair procedures for your ribbed metal siding.

Routine Maintenance

Regular cleaning and inspection are crucial for preventing problems before they become major issues. Cleaning removes dirt, debris, and pollutants that can accelerate corrosion. Regular inspections allow for early detection of damage, allowing for timely and less expensive repairs. For cleaning, a simple solution of mild detergent and water, applied with a soft-bristled brush or sponge, is usually sufficient. Rinse thoroughly with clean water afterward. For stubborn stains, a pressure washer can be used, but maintain a safe distance to avoid damaging the siding. During inspections, check for loose panels, dents, scratches, rust, or signs of insect infestation.

Repairing Minor Dents and Scratches

Minor dents and scratches can often be repaired with relative ease. For small dents, you might be able to gently push them back into place from the back side of the siding. If access is limited, carefully use a rubber mallet to tap the dent from the outside, working gradually to avoid further damage. For scratches, cleaning the area thoroughly is the first step. Then, you can use a touch-up paint that closely matches your siding’s color to minimize their appearance. These touch-up paints are often available from the siding manufacturer or at home improvement stores.

Addressing Rust or Corrosion

Rust is a serious issue that can compromise the structural integrity of your siding. Early detection is key. If you find rust, the affected area needs immediate attention. Start by removing any loose rust with a wire brush. Then, apply a rust converter to neutralize the rust and prevent further spread. After the converter has dried, apply a high-quality primer followed by a coat of exterior-grade paint that matches your siding. For extensive rust damage, replacing the affected panel might be necessary.

Common Problems and Solutions

A table summarizes common problems encountered with ribbed metal siding and their solutions.

| Problem | Solution |

|---|---|

| Loose panels | Tighten screws or replace fasteners as needed. Consider using sealant to prevent future loosening. |

| Dents and scratches | Repair as described above using gentle manipulation or touch-up paint. |

| Rust and corrosion | Remove rust, apply rust converter, prime, and repaint. Replace severely damaged panels. |

| Caulk failure | Remove old caulk, clean the area, and apply new high-quality exterior-grade caulk. |

| Water damage | Identify and repair the source of the leak. Dry the affected area thoroughly and address any resulting damage. |

Cost and Lifespan

Choosing ribbed metal siding involves considering not only its aesthetic appeal but also its long-term cost and durability. Understanding the factors influencing price and lifespan will help you make an informed decision that fits your budget and needs.

Several factors significantly impact the overall cost of ribbed metal siding. Material selection plays a crucial role; aluminum is generally less expensive than steel, but steel offers superior strength and longevity. The thickness of the metal also affects the price; thicker gauges are more durable but cost more. The chosen finish, such as paint color or texture, adds to the expense. Installation costs vary based on the complexity of the project, the size of the house, and the installer’s labor rates. Finally, any necessary preparation work, like removing existing siding, will increase the total cost.

Cost Comparison with Other Cladding Options

Ribbed metal siding often competes in price with vinyl siding, especially when considering its superior lifespan. While initial costs might be slightly higher than vinyl, the long-term savings from reduced maintenance and repairs make it a cost-effective option over the decades. Brick and stone are considerably more expensive upfront, while wood siding, though aesthetically pleasing, requires more frequent maintenance and is susceptible to rot and insect damage, making its overall cost potentially higher in the long run. Fiber cement siding provides a decent alternative, offering durability, but typically falls somewhere between metal and vinyl in terms of initial cost.

Lifespan of Ribbed Metal Siding

The lifespan of ribbed metal siding is highly dependent on the material used and the climate it’s exposed to. Aluminum siding, while less expensive initially, may show signs of wear and tear sooner than steel, particularly in harsh climates with extreme temperature fluctuations and high humidity. Steel siding, being more robust, typically boasts a longer lifespan, often exceeding 50 years with proper maintenance. Coastal areas, where saltwater corrosion is a factor, might see a slightly reduced lifespan for both aluminum and steel, regardless of the thickness of the material. For example, a house in a desert climate might see minimal degradation in its steel siding over 60 years, while a house near the ocean might require repainting or minor repairs after 40 years due to salt spray.

Long-Term Value and Return on Investment

Ribbed metal siding offers excellent long-term value due to its durability and longevity. The reduced maintenance costs and the extended lifespan translate into significant savings over the life of the home. This makes it an attractive investment, potentially increasing the home’s resale value compared to houses clad with materials requiring more frequent replacement or repairs. For instance, a homeowner replacing aging vinyl siding with steel ribbed metal siding might see a quicker return on their investment through lower maintenance and a boosted property value compared to a similar home with continued vinyl siding upkeep. The higher initial cost is often offset by these long-term benefits.

Environmental Impact: Ribbed Metal Siding

Source: sheffieldmetals.com

Ribbed metal siding offers a compelling blend of durability and aesthetics, but its environmental impact is a crucial factor to consider. Understanding the lifecycle of this material, from production to disposal, allows for informed decisions regarding its sustainability. This section will examine the recyclability of the materials, compare its environmental footprint to alternatives, highlight its energy efficiency benefits, and address potential environmental concerns related to its disposal.

The primary materials used in ribbed metal siding are steel and aluminum, both highly recyclable metals. Steel, often coated with zinc or other protective layers, is readily recycled and used in various applications. Aluminum, known for its lightweight and corrosion-resistant properties, also boasts a high recycling rate. The manufacturing process, while energy-intensive, can utilize recycled materials, significantly reducing its overall environmental burden compared to the production of virgin metal. Furthermore, the longevity of metal siding minimizes the need for frequent replacements, further contributing to its environmental advantage.

Recyclability and Material Composition

Steel and aluminum, the main components of ribbed metal siding, possess high recyclability rates. Steel recycling involves melting down scrap metal and reusing it in new products, significantly reducing the need for mining and processing raw materials. Similarly, aluminum recycling consumes considerably less energy than producing aluminum from bauxite ore. The recycling process itself is less energy-intensive and produces fewer greenhouse gas emissions than primary production. The specific recyclability rate varies depending on the local recycling infrastructure and the composition of the siding (e.g., presence of coatings). However, the inherent recyclability of the base materials offers a significant environmental benefit.

Environmental Footprint Comparison, Ribbed metal siding

Compared to other cladding materials, ribbed metal siding often demonstrates a smaller environmental footprint over its lifespan. For instance, vinyl siding, while initially less expensive, requires more frequent replacements due to its shorter lifespan and susceptibility to damage. The production of vinyl also involves the use of fossil fuels and release of volatile organic compounds (VOCs). Wood siding, while a natural material, often requires significant treatment to resist rot and insect infestation, introducing additional chemicals into the environment. Furthermore, the harvesting of wood can contribute to deforestation. While the initial energy required to manufacture metal siding is higher than some alternatives, its extended lifespan and recyclability lead to a smaller overall environmental impact.

Energy Efficiency Benefits

Metal siding contributes to energy efficiency by reflecting sunlight and reducing heat transfer into the building. This reflective property helps to lower cooling costs, particularly in warmer climates. The inherent thermal properties of metal also contribute to improved insulation, leading to potential energy savings in both heating and cooling. The specific energy savings depend on factors such as building design, climate, and insulation levels, but the reflective and conductive properties of metal siding generally offer an advantage over materials with lower reflectivity and higher thermal conductivity. For example, a study conducted by the Lawrence Berkeley National Laboratory showed that reflective roofing materials, including metal, could significantly reduce building cooling loads.

Disposal Considerations

While ribbed metal siding is highly recyclable, its disposal requires proper handling to avoid environmental contamination. Improper disposal, such as landfilling, can lead to the release of harmful substances if the protective coatings are not properly managed. It is crucial to follow local regulations for the disposal of metal siding and to ensure that it is recycled appropriately. Many recycling centers accept metal siding, and some manufacturers even offer take-back programs for their products. Understanding the local recycling infrastructure and adhering to best practices for disposal is essential to minimizing the environmental impact at the end of the siding’s lifespan.

Design Considerations

Source: dreamstime.com

Ribbed metal siding offers a surprising degree of design flexibility, allowing for seamless integration into a variety of architectural styles. Its clean lines and modern aesthetic can complement both contemporary and traditional designs, while its durability and low maintenance make it a practical choice for diverse projects. Understanding how to leverage its visual characteristics is key to maximizing its impact on any building’s curb appeal.

Ribbed metal siding’s versatility stems from its adaptability to different colors, finishes, and rib profiles. A subtle, muted color palette can create a sophisticated, understated look, while bolder colors can make a striking statement. The choice of rib profile – from a barely-there subtle texture to a deeply pronounced groove – dramatically influences the overall visual effect. Furthermore, clever use of materials and design elements can elevate this practical material to a key design feature.

Integration with Architectural Styles

Ribbed metal siding can successfully complement a wide range of architectural styles. For example, a sleek, dark gray ribbed metal siding with a narrow rib profile can create a contemporary industrial aesthetic, particularly when paired with large windows and exposed concrete. Conversely, a warmer tone, like a deep brown or bronze, with a wider rib profile, can lend itself well to a more rustic or farmhouse style. The use of lighter colors and thinner ribs might be preferred for a more minimalist or modern design, while a more pronounced rib and a darker color can add a touch of ruggedness to a more traditional structure. The key lies in carefully selecting the color, finish, and rib profile to complement the overall design theme.

Examples of Successful Applications

Consider a modern residential home featuring a dark gray, horizontally-ribbed metal siding. The clean lines of the siding are accentuated by large, floor-to-ceiling windows, creating a visually stunning contrast between the robust exterior and the open, airy interior. Alternatively, a commercial building might utilize a lighter-colored, vertically-ribbed metal siding to emphasize height and create a sense of elegance. The subtle texture of the siding complements the building’s clean, modern lines, while its durability ensures long-lasting protection. A historic building renovation might incorporate ribbed metal siding in a color that complements the existing structure, showcasing a harmonious blend of old and new architectural styles.

Design Guidelines for Enhancing Curb Appeal

To maximize the curb appeal of a structure using ribbed metal siding, consider the following: Choose a color that complements the surrounding landscape and architectural style. The orientation of the ribs (horizontal or vertical) can significantly impact the perceived size and proportions of the building. Horizontal ribs can make a building appear wider, while vertical ribs can create a sense of height. Careful consideration should be given to the interplay of light and shadow created by the ribs; this can dramatically alter the appearance of the siding throughout the day. Finally, high-quality installation is crucial for a professional and aesthetically pleasing finish.

Design Elements that Complement Ribbed Metal Siding

The success of ribbed metal siding is often amplified by thoughtful selection of complementary design elements. Consider these suggestions:

- Window Styles: Large, modern windows with minimalist frames create a striking contrast against the texture of the siding. Conversely, smaller, traditional windows can add character to a more rustic design.

- Roofing Materials: Standing seam metal roofing creates a cohesive and modern look. Architectural shingles can provide a more traditional feel, depending on the color and style selected.

- Trim and Accents: Wood trim can add warmth and contrast to the metallic surface. Consider using contrasting colors or materials for window frames, doors, and fascia boards to highlight architectural details.

- Landscaping: Strategic landscaping can soften the industrial feel of metal siding, creating a more welcoming and inviting atmosphere. Consider using plants and shrubs to add color and texture to the overall design.

Last Recap

Choosing the right exterior cladding is a significant decision, impacting both the aesthetics and longevity of your building. Ribbed metal siding presents a compelling option, offering a blend of durability, style, and cost-effectiveness. By understanding the various types of metal, installation methods, maintenance requirements, and environmental considerations, you can confidently assess whether ribbed metal siding is the right choice for your project. Remember to factor in your budget, climate, and desired aesthetic when making your final decision. The payoff – a beautiful, long-lasting exterior – is well worth the careful planning.

FAQ Section

Can I install ribbed metal siding myself?

While possible for DIY enthusiasts with experience, professional installation is often recommended, especially for larger projects, to ensure proper water sealing and longevity.

How often should I clean my ribbed metal siding?

Regular cleaning, ideally once or twice a year, using a soft brush and mild detergent, will keep your siding looking its best and prevent dirt buildup.

What’s the warranty on ribbed metal siding?

Warranties vary greatly depending on the manufacturer and type of metal. Check with your supplier for specific details.

Does ribbed metal siding attract lightning?

Metal siding itself doesn’t significantly increase the risk of lightning strikes, but a proper grounding system is always recommended for any building.

Can I paint ribbed metal siding?

Yes, but using a paint specifically designed for metal is crucial for optimal adhesion and durability. Always check the manufacturer’s recommendations.

Comments are closed.