Steel Siding vs Vinyl Siding Cost A Homeowners Guide

Steel siding vs vinyl siding cost: Choosing the right siding for your home is a big decision, impacting both your initial investment and long-term expenses. This guide breaks down the costs of steel and vinyl siding, comparing upfront prices, long-term maintenance, durability, and even resale value. We’ll explore the factors influencing cost variations, from material thickness and style to potential hidden installation expenses. Get ready to make an informed choice!

Understanding the differences between steel and vinyl siding goes beyond just the initial price tag. We’ll delve into the lifespan of each material, projecting costs over several decades, including potential repairs and replacements. We’ll also consider how factors like weather resistance, fire safety, and aesthetic preferences influence your overall investment. By the end, you’ll have a clearer picture of which siding best suits your needs and budget.

Initial Cost Comparison

Choosing between steel and vinyl siding involves careful consideration of upfront costs. While both options offer durable exterior cladding, their initial investment differs significantly due to material costs, labor requirements, and regional pricing variations. This section will break down the costs for a typical 1500 sq ft house, highlighting key factors influencing the final price.

Steel Siding vs. Vinyl Siding Costs for a 1500 sq ft House

The following table provides estimated costs for materials and labor for a 1500 sq ft house. Keep in mind that these are averages, and actual costs can vary based on location, installer, and chosen materials. It’s crucial to obtain multiple quotes from reputable contractors in your area for accurate pricing.

| Item | Steel Siding Cost | Vinyl Siding Cost | Cost Difference |

|---|---|---|---|

| Materials (Siding, Trim, Flashing) | $8,000 – $12,000 | $5,000 – $8,000 | $3,000 – $4,000 (Steel more expensive) |

| Labor (Installation, Prep Work) | $6,000 – $9,000 | $4,000 – $6,000 | $2,000 – $3,000 (Steel more expensive) |

| Total Estimated Cost | $14,000 – $21,000 | $9,000 – $14,000 | $5,000 – $7,000 (Steel more expensive) |

Factors Influencing Initial Cost Variations

Several factors contribute to the variation in initial costs between steel and vinyl siding. These include material specifications, design choices, and regional pricing fluctuations.

Steel siding thickness, gauge (thickness), and style significantly impact the price. Thicker, heavier gauge steel is more durable and expensive. More intricate styles, such as those with embossing or unique panel profiles, also increase the cost. Color choices can also influence price; certain colors may require more complex finishing processes, leading to higher costs.

Similarly, vinyl siding prices vary based on thickness, panel style, and color. Thicker vinyl is more resistant to damage and generally more expensive. More complex designs, such as those mimicking wood grain or stone, often command higher prices. Popular colors may also be slightly more expensive due to higher demand.

Potential Hidden Costs Associated with Installation

Beyond the initial material and labor costs, several hidden expenses can arise during the installation process for both steel and vinyl siding. These should be considered when budgeting for your project.

For steel siding, these hidden costs might include the need for specialized tools and expertise, potentially leading to higher labor charges. The need for additional structural reinforcement or preparation of the underlying wall surface can also add unexpected expenses. For instance, if the existing wall sheathing is damaged or inadequate, repairs will increase the overall cost.

For vinyl siding, potential hidden costs may include the need for extra trim pieces or specialized flashing to accommodate complex architectural features. Unexpected issues with existing siding removal, such as encountering asbestos or lead-based paint, can significantly increase the cost. Additionally, the cost of disposing of old siding materials must be factored in. For example, a house with complex architectural details requiring custom-cut vinyl pieces might see a higher-than-average installation cost.

Long-Term Cost Analysis

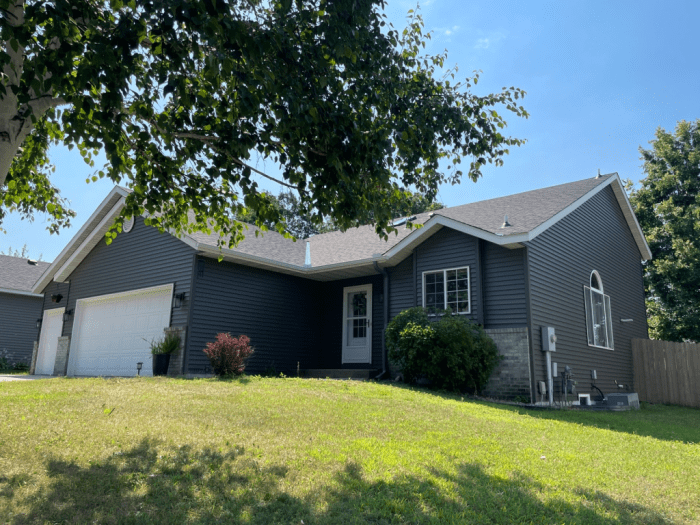

Source: engstromsidingandwindow.com

Choosing between steel and vinyl siding involves considering not just the upfront cost, but also the long-term financial implications. Factors like lifespan, maintenance needs, and potential repair expenses significantly impact the overall cost over time. Let’s delve into a detailed comparison to help you make an informed decision.

Predicting the exact costs over decades is challenging due to fluctuating material prices and unforeseen circumstances. However, by analyzing typical lifespans, maintenance requirements, and potential repair scenarios, we can create a reasonable cost projection for both steel and vinyl siding.

Lifespan and Maintenance Projections

The following Artikels estimated lifespans and maintenance costs for steel and vinyl siding over 20, 30, and 50-year periods. Remember, these are averages and actual costs can vary depending on climate, installation quality, and maintenance practices.

- Steel Siding: Steel siding boasts a remarkably long lifespan, often lasting 50 years or more with proper care. Maintenance is generally minimal, requiring occasional cleaning to remove dirt and debris. Over 20 years, you might expect to spend around $200-$500 on cleaning supplies and minor touch-ups. At 30 years, this could increase to $500-$1000, primarily for repainting or replacing damaged panels due to severe weather. By 50 years, more extensive repairs or even partial replacement might be necessary, potentially costing $2000-$5000 depending on the extent of the damage.

- Vinyl Siding: Vinyl siding typically lasts 20-30 years, though its lifespan can be shorter if exposed to extreme weather conditions or poor installation. Maintenance is relatively low, mainly involving occasional washing to remove dirt and mildew. Over 20 years, you might spend around $100-$300 on cleaning supplies. However, after 20 years, significant fading, cracking, or warping may necessitate replacement, incurring a cost comparable to the initial installation. A 30-year projection would likely include a complete replacement, adding substantially to the long-term cost.

Repair and Replacement Costs

The potential for repairs and replacements significantly influences the long-term cost of siding. Steel siding, while durable, can suffer damage from hail, strong winds, or impacts. Vinyl siding is more susceptible to damage from impacts, extreme temperatures, and UV exposure, leading to cracking, warping, and fading.

- Steel Siding Repairs: Minor dents or scratches in steel siding can often be repaired with touch-up paint. More significant damage, such as deep dents or punctures, may require panel replacement. The cost of replacing individual panels can range from $50 to $200 per panel, depending on size and labor costs.

- Vinyl Siding Repairs: Repairing vinyl siding is often more challenging and less cost-effective than repair of steel siding. Small cracks might be patched, but significant damage usually requires panel replacement. The cost of replacing vinyl siding panels is similar to steel, ranging from $50 to $200 per panel.

- Full Replacement Costs: A full replacement of steel siding after 50 years could cost significantly more than a vinyl siding replacement after 20-30 years, considering the labor and material costs associated with a larger surface area. However, the longer lifespan of steel offsets some of this expense.

Unexpected Cost Examples

Unforeseen events can significantly impact the long-term costs of both siding types. Consider these examples:

- Severe Weather Damage: A major hailstorm or hurricane can cause extensive damage to both steel and vinyl siding, leading to costly repairs or even complete replacement. Insurance coverage may help offset these costs, but deductibles and potential increases in premiums need to be factored in. For instance, a homeowner in a hurricane-prone area might experience significantly higher repair costs for both siding types compared to someone in a calmer climate.

- Pest Infestation: While less common, pests can sometimes nest behind siding, causing damage that may not be immediately apparent. This can lead to unexpected repair and extermination costs for both steel and vinyl siding.

- Improper Installation: Poor installation can lead to premature failure and increased maintenance costs for both siding types. For example, gaps in installation can allow moisture to penetrate, causing rot and mold damage underneath the siding, requiring extensive and costly repairs.

Material Properties and Durability

Source: abclakesarea.com

Choosing between steel and vinyl siding involves understanding their inherent differences in material properties, directly impacting their longevity and maintenance needs. Steel and vinyl react differently to environmental stressors, affecting their lifespan and ultimately, your long-term costs. This section delves into a detailed comparison of their durability and resistance to various forms of damage.

Steel and vinyl siding possess distinct material properties that influence their resistance to damage and overall lifespan. Understanding these differences is crucial for making an informed decision based on your specific needs and budget. The following table summarizes key property differences and their implications.

Material Property Comparison

| Property | Steel Siding | Vinyl Siding | Comparative Analysis |

|---|---|---|---|

| Impact Resistance | High; resists dents and damage from impacts relatively well. | Low; susceptible to dents, cracks, and punctures from impacts. | Steel significantly outperforms vinyl in impact resistance. A falling branch or accidental hit with a tool will likely cause more damage to vinyl. |

| Weather Resistance | Excellent; resists fading, moisture damage, and extreme temperatures. Requires proper coating maintenance. | Good; generally resists moisture and fading, but can become brittle in extreme cold or warp in intense heat. | Both materials are weather-resistant, but steel offers superior longevity and resilience against extreme conditions with proper maintenance. Vinyl’s performance is more susceptible to temperature fluctuations. |

| Fire Resistance | High; non-combustible material; contributes to fire safety. | Low; flammable; poses a fire hazard if exposed to open flames. | Steel’s non-combustible nature makes it a safer choice in terms of fire safety, significantly reducing the risk of fire spread. |

| Maintenance | Low; typically requires occasional cleaning and repainting/recoating every 10-15 years to maintain appearance and protection. | Low; typically requires occasional cleaning; however, repairs are more frequent due to lower impact resistance. | While both require minimal maintenance, steel’s superior durability translates to less frequent repairs. Repainting/recoating is an added cost for steel, but this cost is offset by reduced repair needs. |

| Lifespan | 50 years or more with proper maintenance. | 20-30 years, depending on climate and maintenance. | Steel siding has a significantly longer lifespan than vinyl siding. |

Long-Term Cost Implications of Material Properties

The differences in material properties directly translate to variations in long-term costs. Steel’s superior durability reduces the likelihood of costly repairs and replacements, offsetting the higher initial investment. While vinyl’s lower upfront cost is attractive, the need for more frequent repairs and its shorter lifespan can lead to higher overall costs over the long term. For example, replacing a section of damaged vinyl siding is significantly cheaper than a similar repair on steel; however, the frequency of such repairs for vinyl will accumulate over time. A homeowner might replace vinyl siding entirely within 20 years, while steel siding might last 50 years or more, requiring only occasional maintenance.

Environmental Impact

The environmental impact of both steel and vinyl siding encompasses manufacturing, transportation, and disposal. Steel production is energy-intensive and generates greenhouse gas emissions. However, steel is highly recyclable, mitigating its environmental footprint. Vinyl siding manufacturing relies on petroleum-based products, contributing to carbon emissions. Vinyl is less recyclable than steel and often ends up in landfills. The disposal of both materials presents environmental concerns, highlighting the importance of responsible recycling practices. Choosing a siding material with a lower environmental impact involves considering the entire lifecycle, from production to disposal.

Insurance and Resale Value: Steel Siding Vs Vinyl Siding Cost

Source: cloudfront.net

Choosing between steel and vinyl siding impacts more than just your initial investment; it influences your homeowner’s insurance premiums and your home’s eventual resale value. Understanding these long-term implications is crucial for making an informed decision. Both materials offer different levels of protection and perceived value, affecting how insurance companies assess risk and potential buyers evaluate your property.

Insurance companies often consider the fire resistance and durability of a home’s exterior when calculating premiums. Steel siding, being non-combustible, generally leads to lower insurance rates compared to vinyl siding, which, while fire-retardant, is still susceptible to melting and damage in intense heat. The reduced risk of fire damage associated with steel translates into lower premiums for homeowners. This cost savings can offset some of the higher upfront cost of steel siding over time.

Steel Siding’s Impact on Homeowner’s Insurance

Steel siding’s inherent fire resistance is a key factor in lowering insurance premiums. Many insurance companies offer discounts for homes with fire-resistant materials, recognizing the reduced risk of fire-related claims. For example, a homeowner in a fire-prone area might see a significant reduction in their annual premiums by opting for steel siding instead of vinyl. The exact amount of the discount varies depending on the insurer, location, and other factors, but the savings can be substantial. This financial benefit adds to the overall value proposition of steel siding.

Vinyl Siding’s Impact on Homeowner’s Insurance

While vinyl siding is treated with fire-retardant chemicals, it’s not as inherently fire-resistant as steel. This difference can lead to higher insurance premiums compared to homes with steel siding. Insurance companies assess the risk profile of each property, and the flammability of the siding material plays a significant role in this assessment. While the increase in premiums may not be drastic in all cases, it’s a factor to consider when weighing the costs of different siding options. Homeowners should compare insurance quotes from multiple providers to understand the potential premium differences between steel and vinyl siding.

Resale Value and Buyer Perception, Steel siding vs vinyl siding cost

The perceived durability and longevity of steel siding often translate to a higher resale value. Buyers often associate steel siding with a more robust and low-maintenance exterior, which can increase the appeal of a property. Conversely, vinyl siding, while more affordable upfront, might be perceived as less durable and potentially requiring more frequent repairs or replacements over time, thus potentially impacting the resale price.

Examples of Siding Material Impact on Resale Value

Consider two comparable homes in the same neighborhood: one with steel siding and another with vinyl siding. Assuming all other factors are equal, the home with steel siding is likely to command a higher asking price and sell faster due to the perceived higher quality and longevity of the material. This difference can vary depending on the market conditions and the overall condition of the homes, but the impact of siding choice on resale value is a factor to consider. For example, a recent real estate market analysis in a specific suburban area might show homes with steel siding selling for an average of 2-5% more than comparable homes with vinyl siding, highlighting the potential financial advantage of choosing steel.

Aesthetic Considerations and Customization Options

Choosing between steel and vinyl siding often comes down to personal preference, as both offer a range of aesthetic options, albeit with differing levels of customization. Understanding these differences is crucial for achieving the desired look for your home while staying within your budget. This section will explore the aesthetic versatility and customization options for each siding material.

Steel and vinyl siding each offer a distinct set of aesthetic qualities and customization possibilities. While vinyl offers a wider array of colors and some textural variations, steel siding excels in durability and can mimic the appearance of other materials like wood or stone. The level of customization impacts the overall cost, with more intricate designs and specialized colors typically increasing the price.

Color and Texture Options

Both steel and vinyl siding come in a wide variety of colors, allowing homeowners to match their siding to their home’s architectural style and personal preferences. However, the range and depth of color options, as well as the available textures, differ between the two materials.

- Vinyl Siding: Vinyl siding boasts a vast array of colors, often including more nuanced shades and trendy options. Textures can range from smooth to wood-grain embossed finishes, offering a more natural look. Examples include classic white, deep gray, earthy browns, and even vibrant colors like reds and blues. Wood-grain textures are particularly popular, mimicking the appearance of cedar or other wood species.

- Steel Siding: Steel siding offers a slightly more limited palette compared to vinyl, though still providing a substantial range of colors. However, steel siding often focuses on more durable, fade-resistant finishes. Popular color choices for steel siding include neutral tones like beige, gray, and brown, as well as bolder colors like dark green or navy blue. Textured finishes are less common than with vinyl but can sometimes include subtle variations to mimic a more natural look.

Customization Levels

The degree of customization available for each siding type significantly impacts both the aesthetic outcome and the final cost. While both materials offer options for personalization, the extent of those options differs.

- Vinyl Siding: Vinyl siding offers relatively high customization in terms of color and texture choices. However, complex architectural details or custom shapes are often difficult or impossible to achieve with vinyl. The manufacturing process limits the complexity of designs that can be produced.

- Steel Siding: Steel siding offers less flexibility in terms of readily available color and texture options. However, it allows for greater customization in terms of panel size and shape, enabling the creation of more unique and complex architectural designs. This is because steel can be manufactured into custom shapes and sizes more easily than vinyl.

Impact of Aesthetic Choices on Cost

The aesthetic choices made when selecting siding can significantly impact the overall project cost. More specialized colors, intricate textures, and custom panel designs generally come with a higher price tag, regardless of the material chosen.

For instance, a homeowner opting for a rare or custom-mixed color in vinyl siding might pay a premium compared to choosing a standard color. Similarly, using steel siding with complex shapes or embossed textures will increase the overall expense compared to standard flat panels. The added labor costs associated with installing more complex designs also contribute to the increased price.

Installation Process and Timelines

Source: tonyslifetimeexteriors.com

Getting your new siding installed is a significant step in any home improvement project. The installation process, timeline, and required expertise vary considerably between steel and vinyl siding, impacting both your budget and schedule. Understanding these differences will help you make an informed decision and prepare for the work ahead.

Steel Siding Installation

Steel siding installation generally requires more specialized skills and tools compared to vinyl. The process is more involved due to the material’s weight and the need for precise cuts and fastening. A skilled contractor is usually essential for a professional-looking and long-lasting result.

- Preparation: This involves measuring the house, preparing the walls (repairing damaged areas, ensuring proper sheathing), and establishing a straight baseline for the first course of siding.

- Framing and Furring Strips (if needed): For uneven walls, furring strips provide a level surface for installation. This step is often crucial for steel siding to ensure proper alignment and prevent buckling.

- Siding Installation: Steel panels are typically installed horizontally, overlapping each other. Each panel requires precise cutting and fastening to the wall framing using special screws designed for metal.

- Flashing and Caulking: Proper flashing around windows, doors, and other penetrations is critical to prevent water damage. Caulking seals any gaps to ensure a weathertight installation.

- Finishing: This includes installing trim, soffit, and fascia, completing the overall aesthetic look and protecting exposed edges.

Typical installation time for steel siding ranges from a few days to several weeks depending on the house size and complexity.

Vinyl Siding Installation

Vinyl siding is generally considered easier to install than steel, making it a DIY-friendly option for some homeowners with basic carpentry skills. However, proper installation techniques are still crucial to ensure a durable and aesthetically pleasing result. The lighter weight of vinyl simplifies handling and installation.

- Preparation: Similar to steel siding, preparation involves measuring, wall repair, and establishing a straight baseline.

- Installation: Vinyl panels are typically installed vertically or horizontally, overlapping each other. They are fastened using nails or staples, which are simpler to work with than the specialized screws required for steel.

- J-Channel and Accessories: J-channel is used to finish the edges and corners of the siding, creating a neat and professional look. Other accessories, like starter strips and trim, are also essential.

- Cutting and Fitting: Vinyl siding is relatively easy to cut with standard tools. Precise cuts are important around windows, doors, and other features.

- Finishing: Similar to steel siding, finishing involves installing trim and accessories to complete the installation.

Vinyl siding installation usually takes less time than steel siding, often completed within a few days for smaller homes.

Specialized Skills and Tools

Both steel and vinyl siding installations require specific skills and tools. Steel siding installation demands more advanced skills in metalwork, precision cutting, and fastening techniques. Experienced contractors are often preferred for this type of project. Vinyl siding installation is generally less demanding, though proper techniques are still important to avoid mistakes.

- Steel Siding: Requires specialized metal cutting tools (e.g., tin snips, shears), power drills with appropriate bits for metal screws, and experience in working with metal sheeting.

- Vinyl Siding: Requires basic carpentry tools (e.g., measuring tape, saw, level, hammer or nail gun), but precision is still important for proper fitting and alignment.

Concluding Remarks

Ultimately, the “best” siding—steel or vinyl—depends entirely on your priorities and budget. While vinyl often boasts a lower upfront cost, steel’s superior durability and longevity might translate to significant savings over the long haul. Consider your home’s climate, your desired aesthetic, and your long-term financial goals. Weighing the initial investment against the potential for future repairs and replacements will help you make a smart, cost-effective decision that enhances your home’s value and protects your investment for years to come.

FAQ Compilation

What about financing options for siding installation?

Many home improvement retailers and contractors offer financing plans, including interest-free options or loans with manageable monthly payments. Shop around and compare offers before committing.

Can I install siding myself to save money?

While possible, DIY siding installation is challenging and requires specific skills and tools. Improper installation can void warranties and lead to costly repairs down the line. Consider the time commitment and potential risks before attempting a DIY project.

How does the climate affect siding choice?

In areas with harsh weather (heavy snow, strong winds, extreme temperatures), steel siding’s superior durability is often a better long-term investment. Vinyl can be susceptible to damage in extreme conditions.

What about the environmental impact of disposal?

Both steel and vinyl siding can be recycled, but the processes and associated costs vary. Check with your local waste management facilities for recycling options and disposal fees.

Comments are closed.