Is Fiber Cement Siding Better Than Vinyl?

Is fiber cement siding better than vinyl? That’s the burning question for homeowners looking to upgrade their exterior. Both options offer distinct advantages, but choosing the right one depends on your priorities – longevity, aesthetics, budget, and environmental concerns all play a crucial role. We’ll delve into a head-to-head comparison, examining durability, appearance, cost, environmental impact, and fire safety to help you make an informed decision.

This detailed comparison will explore the pros and cons of each siding type, considering factors like lifespan, maintenance needs, resistance to damage, and the overall cost of ownership over several decades. We’ll also touch upon aesthetic considerations, including color options, texture, and how well each material mimics natural materials like wood or stone. Finally, we’ll examine the environmental footprint and safety aspects of both fiber cement and vinyl siding.

Durability and Longevity

Source: surepulse.com

Fiber cement and vinyl siding offer distinct advantages and disadvantages when it comes to durability and longevity. The best choice depends heavily on your climate, budget, and maintenance preferences. Both materials can last for many years, but their lifespans and maintenance needs differ significantly.

Lifespan Comparison Under Various Weather Conditions

Fiber cement siding generally boasts a longer lifespan than vinyl, often lasting 50 years or more with proper care. Its inherent strength and resistance to moisture, insects, and fire contribute to its superior longevity. Vinyl siding, while durable, typically lasts 20-40 years, depending on the quality and exposure to extreme weather.

Extreme weather events significantly impact the longevity of both materials. For instance, prolonged exposure to intense sunlight can cause vinyl siding to fade and become brittle, potentially cracking under stress. Fiber cement, while less susceptible to fading, can still be affected by extreme temperature fluctuations, leading to minor cracking in harsh climates. Hailstorms can dent vinyl siding easily, requiring costly repairs or replacements. Fiber cement, though more resistant, can still suffer from damage from exceptionally large hailstones. Hurricane-force winds can damage both materials, but fiber cement’s greater strength means it is less likely to be completely ripped away from the house. Coastal areas with high salinity can accelerate the degradation of vinyl siding, while fiber cement’s resistance to moisture makes it a better choice in these environments.

Maintenance Requirements Over 20 Years

The following table lists the maintenance needs of fiber cement and vinyl siding over 20 years. Regular maintenance is crucial for extending the lifespan of both materials and preventing costly repairs.

| Maintenance Task | Frequency (Fiber Cement) | Cost (Fiber Cement) | Material (Fiber Cement) | Frequency (Vinyl) | Cost (Vinyl) | Material (Vinyl) |

|---|---|---|---|---|---|---|

| Cleaning | Every 1-2 years | $50-$200 (depending on house size) | Water, mild detergent, soft brush | Every 1-2 years | $50-$150 (depending on house size) | Water, mild detergent, soft brush |

| Caulk Repair | Every 5-7 years | $100-$300 (depending on areas needing repair) | Exterior-grade caulk | Every 3-5 years | $50-$200 (depending on areas needing repair) | Exterior-grade caulk |

| Painting (Fiber Cement Only) | Every 10-15 years | $1000-$3000 (depending on house size) | Exterior-grade paint | N/A | N/A | N/A |

| Repairing Damaged Sections | As needed | Varies greatly depending on the extent of damage | Replacement panels, fasteners, caulk | As needed | Varies greatly depending on the extent of damage | Replacement panels, fasteners, caulk |

Impact Resistance, Is fiber cement siding better than vinyl

Fiber cement consistently demonstrates superior impact resistance compared to vinyl. This is a crucial factor to consider, especially in areas prone to hailstorms or where accidental impacts are likely.

| Material | Impact Resistance (1-5) |

|---|---|

| Fiber Cement | 4 |

| Vinyl | 2 |

A rating of 4 for fiber cement reflects its ability to withstand significant impacts, such as large hailstones, without sustaining severe damage. While it can crack or chip under extreme force, it’s far less likely to dent or puncture than vinyl. A rating of 2 for vinyl indicates its susceptibility to dents and punctures from even moderate impacts. Hail the size of golf balls can easily dent vinyl siding, creating unsightly blemishes and potentially compromising its weatherproofing capabilities.

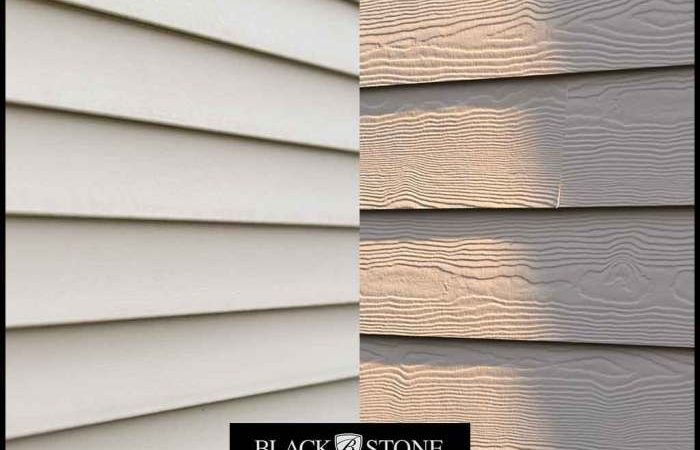

Appearance and Aesthetics: Is Fiber Cement Siding Better Than Vinyl

Choosing between fiber cement and vinyl siding often comes down to personal preference, as both offer a wide variety of styles and colors. However, understanding the aesthetic capabilities of each material is crucial for achieving your desired home exterior look. This section will delve into the visual aspects of each siding type, comparing their color options, textures, and ability to mimic natural materials.

Color and Texture Options

Fiber cement and vinyl siding both boast extensive color palettes. However, their textures differ significantly. Vinyl tends to offer a smoother, more uniform finish, while fiber cement can achieve a more varied and realistic texture. This table illustrates the range of options:

| Material | Colors | Textures | Finishes |

|---|---|---|---|

| Fiber Cement | Wide range, including earth tones, deep blues, and vibrant reds; often allows for custom color matching. | Smooth, wood grain, stucco, rough-hewn, textured; can achieve a highly realistic look. | Matte, semi-gloss, satin |

| Vinyl | Vast array of colors, though some deeper, more saturated hues may fade faster. | Generally smoother, though some manufacturers offer wood grain or textured options. These are often less realistic than fiber cement options. | Smooth, slightly textured; generally limited to matte or semi-gloss finishes. |

Visual Appeal in Different Architectural Styles

The visual impact of siding varies greatly depending on the architectural style of the home.

Victorian Homes: Fiber cement’s ability to mimic wood clapboard or shingles lends itself well to the intricate detailing of Victorian architecture. The variety of textures and paint colors allows for a historically accurate or creatively updated look. Vinyl, while offering a wider range of colors, struggles to capture the depth and complexity of Victorian styling. The smoother texture can appear out of place.

Ranch Homes: Both fiber cement and vinyl work well for ranch homes, which typically feature simpler lines and a more understated aesthetic. The versatility of vinyl in color and affordability makes it a popular choice. Fiber cement offers a more durable and potentially more upscale appearance, particularly with textured finishes mimicking wood or stone.

Modern Homes: Modern architecture often prioritizes clean lines and minimalist aesthetics. Fiber cement siding, with its ability to be installed in large, uninterrupted panels, fits this style perfectly. It can achieve a sleek, sophisticated look. Vinyl can also be used, but the seams can be more visible, potentially detracting from the desired clean aesthetic.

Mimicking Natural Materials

Both fiber cement and vinyl siding attempt to mimic natural materials like wood and stone. However, the success varies considerably.

Fiber cement siding often excels in this area. Manufacturers have made significant advancements in replicating the look and feel of natural wood grain. High-quality fiber cement can be incredibly convincing, offering a realistic wood-like texture and depth. However, less expensive fiber cement options may appear somewhat artificial.

Vinyl siding’s attempts to mimic wood or stone are generally less successful. While some manufacturers offer textured vinyl that resembles wood grain, the effect is often less convincing than fiber cement. The vinyl tends to appear flatter and less realistic. Stone-look vinyl is even less successful, often looking plasticky and artificial.

Cost and Installation

Choosing between fiber cement and vinyl siding involves a significant financial commitment. Understanding the initial costs, ongoing maintenance expenses, and long-term implications is crucial for making an informed decision. This section breaks down the cost factors for both siding options to help you compare.

Initial Costs: Materials, Labor, and Permits

The initial investment for siding includes material costs, labor fees, and permit acquisition. These costs vary depending on location, project complexity, and contractor choices. The following table provides estimated costs for a 2000 sq ft house. Remember these are averages and can fluctuate considerably.

| Cost Category | Fiber Cement Siding | Vinyl Siding |

|---|---|---|

| Materials | $10,000 – $15,000 | $5,000 – $10,000 |

| Labor | $8,000 – $12,000 | $4,000 – $8,000 |

| Permits | $500 – $1,500 | $500 – $1,500 |

| Total Estimated Cost | $18,500 – $28,500 | $9,500 – $19,500 |

Factors Influencing Overall Cost

Several factors significantly influence the final cost of both fiber cement and vinyl siding installations.

House Size and Complexity: Larger houses and those with intricate architectural details (e.g., many dormers, complex trim) require more materials and labor, increasing costs for both siding types. A simple ranch will cost less than a Victorian-style home.

Siding Quality and Features: Higher-end fiber cement siding, featuring thicker planks, enhanced textures, or specialized colors, commands a higher price. Similarly, premium vinyl siding with improved durability and aesthetics will cost more than basic options. For example, choosing a fiber cement board with a realistic wood grain texture will add to the expense compared to a plain, smooth board.

Labor Rates and Contractor Selection: Labor costs vary geographically and depending on the contractor’s experience and reputation. Highly skilled and experienced contractors often charge more. Obtaining multiple bids from reputable contractors is essential to ensure competitive pricing.

Region and Local Regulations: Building codes and permit fees differ across regions. Areas with higher labor costs or stricter building regulations will likely have higher overall siding installation costs. Permitting processes in some areas may also take longer, impacting the project timeline.

Long-Term Cost Implications

While vinyl siding initially costs less, the long-term costs of maintenance, repairs, and potential replacements should be considered. Fiber cement, despite its higher upfront cost, offers greater longevity and potentially lower long-term expenses.

| Cost Category (30-year period) | Fiber Cement Siding | Vinyl Siding |

|---|---|---|

| Maintenance (cleaning, minor repairs) | $1,000 – $2,000 | $1,500 – $3,000 |

| Major Repairs (e.g., storm damage) | $1,000 – $3,000 (potential for fewer repairs) | $2,000 – $5,000 (higher likelihood of repairs) |

| Replacement | $0 – $5,000 (depending on lifespan) | $10,000 – $20,000 (likely to require replacement) |

| Total Estimated 30-Year Cost | $2,000 – $10,000 | $13,500 – $28,000 |

Environmental Impact

Source: americanroofingco.com

Choosing between fiber cement and vinyl siding involves considering their respective environmental footprints. Both materials have impacts throughout their lifecycles, from raw material extraction and manufacturing to transportation, installation, and eventual disposal. Understanding these impacts helps homeowners make informed decisions aligned with their environmental values.

Manufacturing, transportation, and disposal of fiber cement and vinyl siding contribute differently to overall environmental impact. Fiber cement, a composite material, generally has a higher upfront embodied carbon footprint due to the energy-intensive cement production process. However, its longer lifespan can offset this initial impact over time. Vinyl siding, while often touted as recyclable, presents challenges in its actual recycling rate and can contribute to landfill waste.

Lifecycle Carbon Footprint Comparison

The following table offers a simplified comparison of the carbon footprint of fiber cement and vinyl siding. Precise figures vary based on manufacturing processes, transportation distances, and specific product formulations. These values represent estimates based on industry averages and should be considered approximate.

| Lifecycle Stage | Fiber Cement (kg CO2e per m²) | Vinyl Siding (kg CO2e per m²) |

|---|---|---|

| Manufacturing | 80-120 | 50-80 |

| Transportation | 5-15 | 3-10 |

| Installation | 2-5 | 1-3 |

| Disposal/Recycling | 10-20 (depending on recycling rate) | 20-40 (low recycling rate, significant landfill contribution) |

| Total Estimated Range | 97-160 | 74-133 |

Recyclability and Sustainability

Fiber cement siding is not typically recycled in the same way as other materials. Disposal often involves sending it to landfills. However, some components, like wood fibers, can potentially be recovered through specialized processes. Efforts are ongoing to improve the end-of-life management of fiber cement. Vinyl siding’s recyclability is often cited as a benefit, yet the reality is that many vinyl siding recycling programs are limited in scope and accessibility. A significant portion of vinyl siding ends up in landfills, contributing to persistent plastic waste. Therefore, while technically recyclable, the practical recycling rate remains low.

Health and Safety Concerns

Manufacturing and installation of both fiber cement and vinyl siding present potential health and safety concerns. Appropriate precautions are essential to mitigate risks.

- Fiber Cement: During manufacturing, exposure to silica dust can lead to silicosis, a serious lung disease. Installation can involve cutting and handling the material, potentially generating dust requiring respiratory protection. Proper ventilation and personal protective equipment (PPE) such as respirators and eye protection are crucial.

- Vinyl Siding: Vinyl siding manufacturing involves the use of PVC, a material containing volatile organic compounds (VOCs) which can contribute to air pollution. During installation, the use of sharp tools and ladders poses risks of cuts and falls. Proper handling of tools and use of appropriate safety gear are essential.

Fire Resistance and Safety

Fiber cement and vinyl siding offer vastly different levels of fire protection for your home. Understanding these differences is crucial for ensuring the safety of your family and property. This section will compare the fire resistance of each material, examining their performance in fire scenarios and relevant building codes.

Fiber cement siding, a composite material of cement, cellulose fibers, and other additives, possesses significantly superior fire resistance compared to vinyl siding. This inherent difference stems from the materials’ composition and how they react to high temperatures.

Fire Resistance Ratings and Standards

While specific ratings can vary based on the manufacturer and the precise formulation of the fiber cement product, fiber cement siding generally exhibits a Class A fire rating according to ASTM E-84, the standard test method for surface burning characteristics of building materials. This is the highest rating achievable, indicating minimal flame spread and smoke development. In contrast, vinyl siding typically receives a Class C rating, indicating a higher potential for flame spread and smoke generation. This difference reflects the fact that vinyl, a thermoplastic polymer, will melt and ignite at relatively low temperatures. The Class A rating for fiber cement translates to a much slower spread of fire across the siding’s surface during a fire event.

Fire Performance in Real-World Scenarios

In a fire, fiber cement siding will char and possibly crack under intense heat, but it will not readily melt or contribute to the rapid spread of flames. The non-combustible nature of its components significantly reduces the risk of the fire escalating quickly along the exterior of the building. Conversely, vinyl siding will readily ignite and melt, producing significant amounts of smoke and toxic fumes. The molten vinyl can also drip and ignite other flammable materials nearby, accelerating the fire’s spread. This behavior significantly increases the risk to occupants and property. Imagine a scenario where a small fire starts near the exterior wall: with fiber cement, the fire would likely remain localized; with vinyl, it could rapidly engulf the entire house.

Safety Regulations and Building Codes

Many building codes incorporate fire safety regulations that directly influence the choice of exterior cladding. While specific requirements vary by location, jurisdictions often favor the use of Class A rated materials, like fiber cement, in areas with high fire risk or where dense residential construction necessitates higher fire safety standards. The use of vinyl siding might be restricted or require additional fire-retardant measures in such situations. Local building departments are the best source for specific code requirements in your area. Consult your local building codes and fire marshal to ensure compliance before selecting siding materials.

Ending Remarks

Source: homedit.com

Ultimately, the “better” siding choice between fiber cement and vinyl depends entirely on your specific needs and priorities. Fiber cement often wins out in terms of durability and longevity, offering superior protection against the elements and lasting significantly longer. However, it comes with a higher upfront cost. Vinyl, on the other hand, provides a more budget-friendly option with a wide array of colors and styles, though its lifespan and resistance to damage are generally less impressive. Carefully weigh the long-term costs, maintenance requirements, and aesthetic preferences to determine which siding best suits your home and budget.

Expert Answers

Can I install fiber cement or vinyl siding myself?

While DIY installation is *possible* for both, it’s generally recommended to hire professionals, especially for fiber cement, due to its weight and the need for precise cutting and installation. Vinyl is easier for DIY but mistakes can be costly.

How does each siding type handle insect infestation?

Fiber cement is highly resistant to insect damage, unlike vinyl which can be susceptible to certain pests, particularly termites in some climates. Proper installation and regular inspection are crucial for both.

What about repainting or replacing damaged sections?

Repainting fiber cement is possible, but more involved than vinyl, which can be easily replaced section by section. Repairing damage is generally easier with vinyl.

Which siding type offers better insulation?

Both offer some insulation, but neither is a primary insulation material. The insulating value is largely dependent on the underlying wall construction and additional insulation installed.

Does the siding choice affect my home insurance?

Some insurance companies may offer discounts for homes with more durable siding like fiber cement, but this varies by location and insurer. It’s best to check with your insurance provider.

Comments are closed.