Cost of Metal Siding vs Hardie Board A Homeowners Guide

Cost of metal siding vs Hardie board: Choosing the right siding for your home is a big decision, impacting both your budget and the look of your property. This guide breaks down the costs, from initial material expenses and installation labor to long-term maintenance and potential repairs. We’ll explore the price differences across various regions, considering factors like material type and regional labor rates, to help you make an informed choice.

We’ll delve into the pros and cons of each material, comparing their lifespans, environmental impact, and aesthetic versatility. Understanding the total cost of ownership, including warranties and potential future expenses, is crucial. By the end, you’ll have a clear picture of which siding best fits your needs and budget.

Initial Costs

Source: bestonbudget.com

Choosing between metal siding and Hardie board involves a significant upfront investment. Understanding the price differences and factors influencing those prices is crucial for budgeting and making an informed decision. This section will break down the initial material costs, considering regional variations and additional expenses.

Material Prices by Region

The cost of both metal siding and Hardie board fluctuates depending on location. Transportation costs, local labor rates, and market demand all play a role. The following table provides estimated average prices per square foot, but these are generalizations and should be verified with local suppliers. Remember, these are estimates and actual prices may vary significantly.

| Region | Metal Siding Price ($/sq ft) | Hardie Board Price ($/sq ft) | Price Difference Percentage |

|---|---|---|---|

| Northeast US | $4.50 – $7.00 | $3.00 – $5.00 | 25% – 40% higher for metal (depending on specific prices within the ranges) |

| Southeast US | $4.00 – $6.50 | $2.50 – $4.50 | 33% – 44% higher for metal (depending on specific prices within the ranges) |

| Midwest US | $4.25 – $6.75 | $2.75 – $4.75 | 36% – 42% higher for metal (depending on specific prices within the ranges) |

| West Coast US | $5.00 – $8.00 | $3.50 – $6.00 | 29% – 33% higher for metal (depending on specific prices within the ranges) |

Factors Influencing Price Fluctuation, Cost of metal siding vs hardie board

Several factors contribute to the price variability of both metal and Hardie board siding. For metal siding, the type of metal (e.g., aluminum, steel, zinc) significantly impacts the cost. Steel is generally less expensive than aluminum, while zinc alloys tend to be more costly due to their durability and corrosion resistance. The gauge (thickness) of the metal also affects the price; thicker gauges are more expensive but more durable.

For Hardie board, the type of fiber cement board influences the cost. Lap siding is typically less expensive than vertical planks or other specialized profiles. The finish (e.g., painted, primed) also adds to the cost. Market demand, particularly during periods of high construction activity, can drive up prices for both materials. Supply chain disruptions can also cause price increases.

Cost Breakdown of Additional Components

Beyond the base material cost, several additional components contribute to the overall expense. These include:

* Fasteners: Nails, screws, and other fasteners are needed for installation. The type and quantity will depend on the siding material and project size.

* Trim: J-channel, corner trim, and other finishing pieces are essential for a professional look. These are typically sold separately and add to the overall cost.

* Flashing: This waterproof material is crucial around windows, doors, and other openings to prevent water damage.

* Underlayment: This moisture barrier is placed beneath the siding to protect the building’s structure. The type and cost vary depending on the climate and building requirements.

* Labor: While not directly a material cost, labor represents a substantial portion of the total project expense. This will vary significantly depending on location and the complexity of the project.

Installation Costs: Cost Of Metal Siding Vs Hardie Board

Getting your new siding installed is a significant part of the overall project cost. This section breaks down the labor costs for both metal and Hardie board siding, helping you understand what influences the final price. Remember that these are estimates, and your actual costs will depend on several factors.

Labor costs for siding installation are primarily determined by the project’s size, complexity (e.g., intricate trim work, unusual angles), and regional differences in labor rates. Highly skilled installers command higher rates, and projects requiring more precision and time naturally cost more. Furthermore, material accessibility can impact the overall time and therefore the cost. Difficult-to-reach areas, for instance, require more time and specialized equipment, thus increasing labor expenses.

Labor Costs per Square Foot

The table below provides estimated labor costs per square foot for installing metal and Hardie board siding. These figures are averages and can vary significantly based on the factors mentioned above. Always get multiple quotes from reputable contractors in your area for an accurate estimate.

| Siding Type | Estimated Labor Cost per Square Foot (USD) | Range (USD) |

|---|---|---|

| Metal Siding | $2.50 – $5.00 | This range accounts for variations in project complexity and regional labor rates. A simple installation on a smaller home might fall towards the lower end, while a large, complex project with intricate detailing could reach the higher end. |

| Hardie Board Siding | $3.00 – $6.00 | Similar to metal siding, the cost variation is due to factors such as project size, complexity, and regional labor rates. More intricate designs and larger projects typically fall within the higher range. |

Specialized Skills and Their Impact on Labor Costs

Metal siding installation requires experience with specialized tools and techniques. Installers need to be proficient in cutting, measuring, and fastening metal panels accurately to ensure a watertight and aesthetically pleasing finish. Improper installation can lead to leaks and damage, making skilled labor crucial. This expertise justifies the higher hourly rates often charged by experienced metal siding installers.

Hardie board installation, while seemingly simpler, also demands skill. Installers need to understand proper fastening techniques to prevent cracking or damage to the fiber cement boards. They also need to be adept at cutting and fitting the boards around windows, doors, and other architectural features, requiring precision and attention to detail. Improper installation can lead to water damage, and experienced installers are better equipped to prevent such issues.

Average Installation Time for a Standard-Sized Home

The average installation time for a standard-sized home varies depending on the siding type and the complexity of the project. Metal siding installations, often requiring specialized tools and techniques, can take slightly less time than Hardie board installations for a straightforward project. However, intricate designs and larger surface areas will naturally extend the installation time for both types of siding.

For a typical 2,000 square foot home, a metal siding installation might take a crew of 2-3 experienced installers 3-5 days, while a Hardie board installation could take 4-7 days. These are estimates, and the actual time may vary significantly depending on site conditions, weather, and the complexity of the project. A home with many intricate architectural details, for example, will invariably take longer to complete.

Long-Term Costs

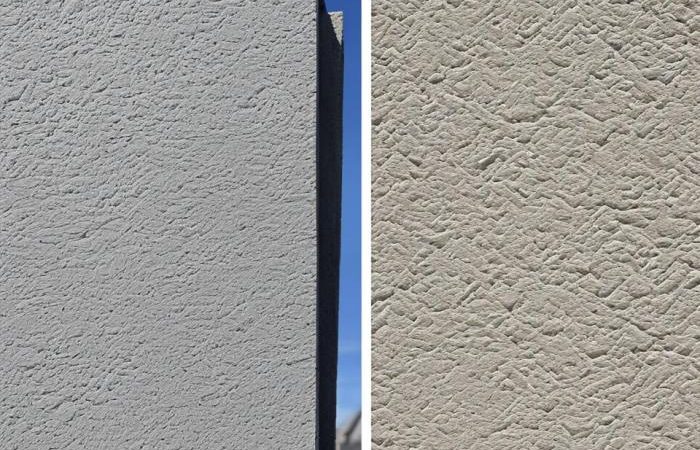

Source: elitehomeexteriorsnw.com

Choosing between metal siding and Hardie board involves considering not just upfront costs, but also the long-term expenses associated with maintenance and repairs. Both materials have their pros and cons in this area, and understanding these differences is crucial for making an informed decision. This section will break down the long-term costs, helping you weigh the advantages and disadvantages of each option.

Maintenance Requirements

Regular maintenance can significantly extend the lifespan of your siding and reduce the likelihood of costly repairs. Neglecting maintenance, however, can lead to premature deterioration and expensive fixes down the road. Let’s compare the typical maintenance tasks for metal and Hardie board siding.

- Metal Siding: Metal siding generally requires minimal maintenance. Periodic cleaning with a pressure washer (low pressure to avoid damage) to remove dirt and debris is recommended. Inspecting for loose panels or signs of rust, especially in coastal areas or areas with high humidity, is also important. Regularly checking for and addressing any minor scratches or dents can prevent larger issues.

- Hardie Board Siding: Hardie board, being a cement-based product, is more susceptible to moisture damage. Regular cleaning, similar to metal siding, is necessary. However, you’ll also need to inspect for cracks, chips, or signs of water damage more frequently. Painting or repainting every 5-10 years (depending on climate and exposure) is often necessary to maintain the appearance and protect the material from the elements. Caulking around windows and doors should also be inspected and reapplied as needed.

Repair Costs

While both metal and Hardie board siding are durable, repairs will eventually be needed. The cost of these repairs varies depending on the extent of the damage and the labor costs in your area. The following table provides estimates for common repair scenarios. These are average costs and may vary significantly based on location and the specific contractor.

| Issue | Metal Siding Repair Cost | Hardie Board Repair Cost | Cost Difference |

|---|---|---|---|

| Replacing a single damaged panel | $100 – $300 | $150 – $400 | $50 – $100 |

| Repairing minor dents or scratches | $50 – $150 | $75 – $200 (often requires repainting) | $25 – $50 |

| Repairing water damage (small area) | $100 – $250 | $200 – $500 (often requires more extensive repairs) | $100 – $250 |

| Major water damage repair (large area) | $500 – $2000 (potentially entire section replacement) | $1000 – $4000 (potentially entire section replacement) | $500 – $2000 |

Material Lifespan and Long-Term Cost Impact

The lifespan of your siding directly affects your long-term costs. A longer-lasting material will generally require fewer repairs and replacements over time, leading to lower overall expenses.

- Metal Siding: Metal siding is known for its exceptional durability, with a lifespan often exceeding 50 years, sometimes even reaching 75 years or more with proper maintenance. This long lifespan significantly reduces the frequency of repairs and replacements, resulting in lower long-term costs.

- Hardie Board Siding: Hardie board siding typically lasts 30-50 years, depending on climate and maintenance. While it’s more durable than vinyl, it requires more frequent maintenance, including repainting, which adds to the overall long-term cost. Its susceptibility to moisture damage also means that repairs are more likely to be needed compared to metal siding.

Environmental Impact & Sustainability

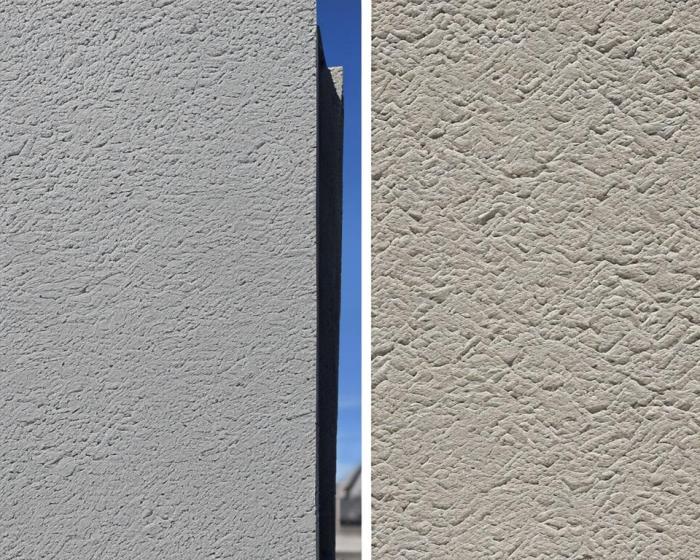

Source: homedit.com

Choosing between metal siding and Hardie board involves considering not just upfront costs but also their long-term environmental impact. Both materials have their lifecycle stages – from raw material extraction and manufacturing to transportation, installation, and eventual disposal – each contributing to their overall environmental footprint. Understanding these impacts is crucial for making a sustainable and responsible choice.

The environmental impact of metal siding and Hardie board differs significantly across their life cycles. Metal siding, primarily made from steel or aluminum, requires substantial energy input during its manufacturing process. Hardie board, a fiber cement product, also demands energy for its production, but the specific energy consumption varies depending on the manufacturing processes and the cement content. Transportation distances further influence the carbon footprint of both materials, with longer distances resulting in higher emissions. Finally, disposal and recyclability also play a role; metal siding is generally more easily recycled than Hardie board.

Manufacturing Processes and Energy Consumption

Steel production, a major component of metal siding manufacturing, is energy-intensive, relying heavily on fossil fuels. Aluminum production, while also energy-intensive, uses different processes with varying environmental consequences. Conversely, Hardie board’s manufacturing involves combining cement, cellulose fibers, and other additives. The cement industry itself is a significant emitter of greenhouse gases, primarily carbon dioxide. Therefore, the embodied carbon – the total greenhouse gas emissions associated with a product’s entire lifecycle – is higher for both materials than for some other alternatives, though the exact amounts vary depending on the specific manufacturing processes and the source of energy used. For example, a study by the University of California, Berkeley, found that the embodied carbon of steel siding can be significantly higher than that of fiber cement siding, especially when considering transportation and end-of-life impacts. However, other studies have shown varying results depending on the specific materials and manufacturing processes used.

Transportation and Distribution

The distance materials need to travel from the manufacturing plant to the construction site significantly impacts their environmental footprint. Transporting heavier materials, like Hardie board, over long distances will generally have a higher carbon footprint than transporting lighter metal siding the same distance. The mode of transportation also matters; using rail or sea freight can reduce emissions compared to road transport. Consideration should be given to sourcing materials locally whenever possible to minimize transportation-related emissions.

Recyclability and Use of Recycled Content

Metal siding boasts higher recyclability rates compared to Hardie board. Steel and aluminum are readily recyclable materials, allowing for a circular economy approach. However, the recycling rate depends on the infrastructure available for collection and processing. Hardie board, while some components can be recycled, presents more challenges due to the mixture of materials. The use of recycled content in the manufacturing process also varies between the two. Some manufacturers utilize recycled aluminum in metal siding, and some use fly ash or other recycled materials in the production of Hardie board. The percentage of recycled content can significantly influence the overall environmental impact.

Embodied Carbon and Long-Term Costs

Embodied carbon, as previously mentioned, represents the total greenhouse gas emissions associated with a product’s entire lifecycle. A higher embodied carbon signifies a greater contribution to climate change. While the initial cost of metal siding or Hardie board might be similar, the embodied carbon should be factored into the long-term cost assessment. A lower embodied carbon suggests a more sustainable choice, potentially leading to lower long-term environmental costs. While there isn’t a direct monetary value assigned to embodied carbon, various carbon accounting methodologies exist to quantify its impact, which is increasingly considered by environmentally conscious builders and homeowners. For example, a building project aiming for LEED certification will carefully evaluate the embodied carbon of all materials used.

Aesthetic Considerations & Design Options

Source: sfwconstruction.com

Choosing between metal siding and Hardie board involves more than just durability and cost; aesthetics play a crucial role in enhancing your home’s curb appeal and overall value. Both options offer a wide range of styles and finishes, allowing for considerable design flexibility to complement different architectural styles and personal preferences. The right choice depends on your vision for your home’s exterior.

Metal siding and Hardie board provide distinct aesthetic qualities. Metal siding, for instance, offers a modern, sleek look, while Hardie board can achieve a more traditional, classic feel, depending on the chosen style and finish. Understanding these differences is key to making an informed decision.

Metal Siding Aesthetic Options

Metal siding boasts a remarkable versatility in achieving various aesthetic looks. Color options are virtually limitless, ranging from classic earth tones to vibrant modern shades. Textures can mimic wood grain, stone, or even stucco, broadening the design possibilities significantly. Styles vary from traditional panels to contemporary vertical designs or even sleek, flat profiles. This adaptability makes metal siding suitable for a wide array of architectural styles.

- Modern Farmhouse: A dark gray or black metal siding with a subtle texture can beautifully complement the clean lines and simple forms of a modern farmhouse.

- Contemporary: Sleek, flat panels in a bold color like deep blue or charcoal gray create a striking and sophisticated look for a contemporary home.

- Mid-Century Modern: Horizontal metal siding in a muted tone, such as beige or light gray, can evoke the clean lines and simplicity of mid-century architecture.

The choice of metal siding significantly impacts curb appeal. A well-chosen color and texture can dramatically improve the home’s visual appeal, increasing its market value. For example, a home with outdated siding replaced with modern metal siding in a complementary color scheme could see a significant boost in its appraised value. Conversely, poorly chosen metal siding could detract from the home’s overall aesthetic, potentially reducing its value.

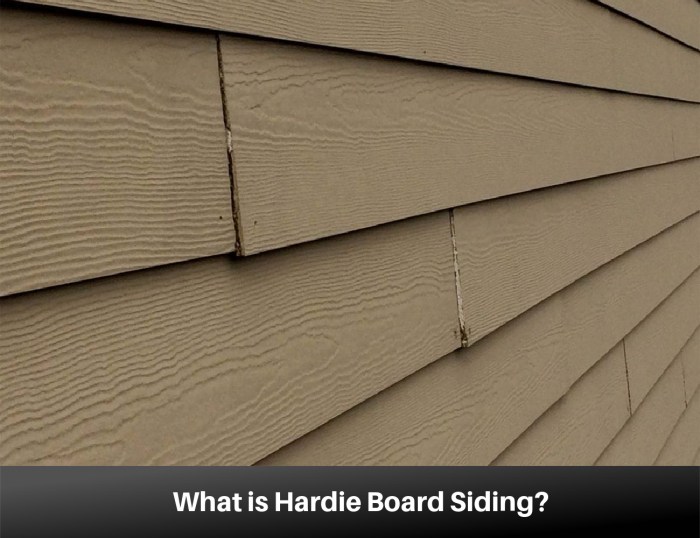

Hardie Board Aesthetic Options

Hardie board, a fiber cement product, offers a more traditional aesthetic. While it doesn’t have the same extensive color range as metal siding, it provides a wider variety of textures and styles that emulate natural materials. Colors are often more subdued, lending themselves to classic or traditional architectural styles. The textures can convincingly replicate wood shakes, clapboard, or even stucco.

- Traditional Colonial: Hardie board with a clapboard profile and a neutral color palette, such as cream or white, perfectly complements the classic lines of a Colonial-style home.

- Victorian: Detailed trim and a variety of textures, such as wood shakes or shingles, in a Hardie board installation can create a richly detailed Victorian aesthetic.

- Craftsman: Hardie board siding with a horizontal lap profile and earthy tones, such as browns and greens, creates a warm and inviting Craftsman style exterior.

Hardie board’s impact on curb appeal is significant. Its ability to convincingly mimic traditional materials like wood can add a sense of timeless elegance. A well-maintained Hardie board exterior contributes to a higher perceived property value, while poorly maintained or inappropriately chosen Hardie board can negatively affect a home’s overall aesthetic and market value. A real-life example could be comparing two similar homes in a neighborhood; the one with well-maintained Hardie board siding, properly painted and detailed, will typically command a higher price.

Warranty & Guarantees

Choosing between metal siding and Hardie board often involves considering the long-term investment, and a crucial aspect of that is the warranty offered by manufacturers. Understanding the terms and conditions of these warranties can significantly impact your overall cost and peace of mind. Both materials come with warranties, but they differ in scope and duration.

Manufacturers’ warranties for both metal siding and Hardie board typically cover defects in materials and workmanship. However, the specifics, including the length of coverage and what constitutes a covered defect, vary considerably between brands and even product lines within a brand. Careful review of the fine print is essential before making a final decision.

Warranty Coverage Differences

Metal siding warranties often cover issues like rust, corrosion, and paint fading for a period ranging from 20 to 50 years, depending on the manufacturer and the specific product. Hardie board warranties, on the other hand, usually focus on structural integrity and moisture resistance, with coverage periods typically lasting 30 years or more. These warranties, however, may not cover damage caused by improper installation, extreme weather events, or normal wear and tear.

Warranty Conditions and Limitations

Most manufacturers will void the warranty if the siding is not installed according to their specifications. This includes using the correct fasteners, following proper ventilation guidelines, and ensuring appropriate flashing and sealing around windows and doors. Damage caused by acts of God, such as hailstorms or hurricanes, is generally not covered. Similarly, damage resulting from neglect, such as failing to address minor issues promptly, might invalidate the warranty. Specific exclusions often detailed in the warranty documents, so careful reading is paramount.

Warranty Implications on Long-Term Costs

A comprehensive warranty can significantly reduce long-term costs by protecting you from unexpected repairs or replacements. For example, if your metal siding develops rust after only a few years due to a manufacturing defect, a strong warranty could cover the cost of replacement, saving you thousands of dollars. Conversely, a limited or poorly worded warranty could leave you shouldering the expense of repairs or replacements well before the expected lifespan of the material. Considering the length and comprehensiveness of the warranty alongside the initial cost is a crucial factor in making an informed decision. For instance, a slightly more expensive metal siding with a 50-year warranty might be a more cost-effective choice in the long run compared to a cheaper option with only a 10-year warranty, especially considering the potential cost of replacing the siding before its intended lifespan.

Closing Notes

Ultimately, the best siding choice depends on your priorities and circumstances. While metal siding often boasts lower initial costs and longer lifespan, Hardie board offers a more traditional aesthetic and potentially lower maintenance in certain climates. Carefully weigh the initial investment against long-term costs, considering factors like your home’s style, climate, and your personal preferences for maintenance. By thoughtfully considering all aspects presented here, you can confidently select the siding that maximizes value and beauty for your home.

Popular Questions

Can I install metal or Hardie board siding myself?

While DIY is possible, both types require specific skills and tools. Improper installation can void warranties and lead to costly repairs. Professional installation is generally recommended.

What about insurance considerations?

Your homeowner’s insurance may have specific requirements regarding siding materials. Check your policy or contact your insurer to discuss coverage implications before making a decision.

How does climate affect siding choice?

Metal siding excels in extreme weather, resisting hail and strong winds. Hardie board performs well in most climates but may require more frequent maintenance in harsh conditions.

Are there financing options available for siding?

Many home improvement retailers and contractors offer financing plans. Explore options to see if financing can help manage the upfront costs.

What’s the typical warranty length for each siding type?

Warranty lengths vary by manufacturer but typically range from 20-50 years for both metal and Hardie board siding. Always check the specific terms and conditions.

Comments are closed.